Ultrasonic welding is typically used in industrial applications, but with advancements in technology, more and more homeowners can benefit from this efficient and eco-friendly welding method. This article will introduce several practical applications of ultrasonic welding for home use, along with its advantages, to help you understand the potential of this technology.

What is Ultrasonic Welding?

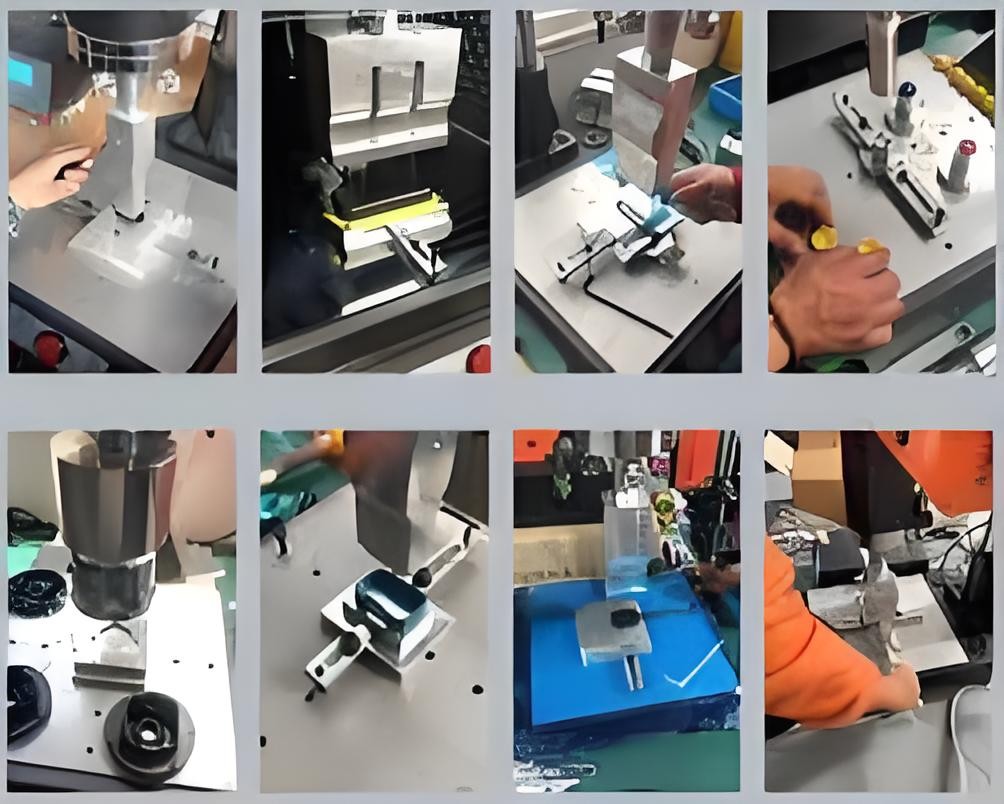

Ultrasonic welding is a method that uses high-frequency vibrations to join two materials together. The vibrations, emitted by an ultrasonic device, generate localized heat on the materials' surfaces, causing them to melt and fuse. This process doesn't require any welding materials or adhesives, making it a clean and efficient welding method.

Applications of Ultrasonic Welding for Home Use

Plastic Welding and Repair Ultrasonic welding is highly effective in plastic welding. Home users can use it to repair broken plastic items, such as appliance housings, toys, or electronic device casings, or even create custom plastic parts. It requires no additional welding materials, and the welded joints are strong and aesthetically pleasing.

Electronic Device Repair Ultrasonic welding is particularly useful for repairing electronic devices around the home. It can be used for circuit board repairs, fixing contact points, or connecting wires, helping to prevent overheating and damage to other delicate components during the welding process.

Leather and Fabric Welding In addition to metals and plastics, ultrasonic welding can also be used to weld leather and fabrics. Home users can use this technology to create leather accessories, repair leather furniture, or even perform custom fabric welding for clothing items.

Small Craft and Jewelry Making Ultrasonic welding is perfect for small craft projects, such as jewelry or decorative items. Home users can join tiny components with precision, ensuring that the connections are strong without the need for traditional adhesives, which may lead to weak or unstable joints.

Home Medical Equipment Assembly Ultrasonic welding can be useful in assembling simple home medical devices, such as blood glucose monitors or thermometers. It ensures precise connections between components, reducing the risk of damage and extending the lifespan of the equipment.

Advantages of Ultrasonic Welding

High Efficiency Ultrasonic welding can complete joints in a matter of seconds, significantly boosting productivity. This is especially useful for home users who need quick repairs or custom creations.

Eco-Friendly and Safe Unlike traditional welding methods, ultrasonic welding does not require welding materials, chemicals, or solvents. This makes it a more eco-friendly and safer option, particularly for home use.

Precise Joining Ultrasonic welding offers precise control, making it ideal for joining tiny parts without causing damage or deformation to the materials. This precision is especially important for home users working on delicate or small-scale projects.

No Heat Damage One major advantage of ultrasonic welding is that it generates minimal heat, preventing heat damage to sensitive materials. This makes it a safer option for welding delicate materials that may be prone to warping or degradation under high temperatures.

Cost-Effective While the initial investment in ultrasonic welding equipment may be higher, the time saved and reduction in material waste make it a cost-effective solution in the long term. For home users who need frequent small-scale welding, ultrasonic welding is a wise investment.