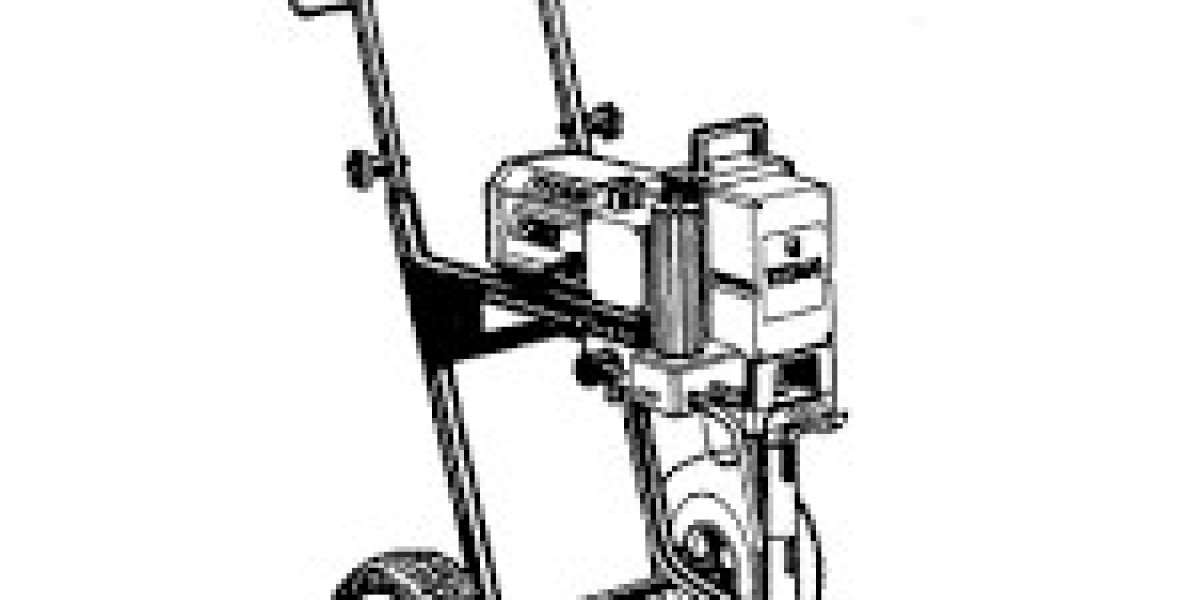

Spray equipment is a great tool for painting walls, furniture, fences, and more. Whether you’re a professional or a DIY enthusiast, a sprayer saves you time and effort. But like any tool, spray equipment needs care. Over time, parts wear out, and performance drops.

Instead of buying a new unit, you can bring your sprayer back to life by replacing key components. This process—known as revitalization—can extend the life of your equipment, improve results, and save money.

Why Spray Equipment Wears Out?

Sprayers deal with high pressure and constant movement. They push paint, stain, or coatings through narrow passages. This creates stress on the internal parts. As you use the sprayer more, wear becomes normal.

In addition, paint and chemicals can build up over time. If you don’t clean the equipment after each use, it gets worse. Even the best sprayers break down when maintenance is ignored. Harsh environments like extreme heat or cold can also damage parts.

Warning Signs You Need Replacement Parts

Before your sprayer stops working, it usually gives signs that something is wrong. Pay attention to these red flags:

Uneven spray pattern: If the paint isn’t coming out smooth, your tip or nozzle may be worn.

Loss of pressure: This can point to problems in the pump or hose.

Leaks or drips: Worn seals or cracked hoses can cause this.

Clogs: Filters or screens might be dirty or damaged.

Frequent stalling or noise: Indicates internal parts need attention.

Don't wait for a total breakdown. These signs mean it's time to act.

Essential Parts Worth Replacing

You don’t always need to replace the whole sprayer. In most cases, a few fresh parts can restore full power and precision. Here are the top components to check:

1. Nozzles and Tips

Spray tips decide the pattern and flow of paint. Over time, the tip wears out and changes the spray shape. This leads to uneven coats or wasted paint.

Replacing a worn tip is simple and cheap. It can instantly improve your results. Always match the tip size to your project needs.

2. Hoses and Connectors

Sprayer hoses carry liquid under high pressure. Old hoses may crack, leak, or even burst. Loose connectors can cause spray loss or messy leaks.

New hoses improve safety and give a steady flow. Choose ones with flexible, kink-free designs for better handling.

3. Filters and Screens

Filters trap dirt and prevent clogs. If ignored, they can block flow or damage the pump. Replace filters often, especially after heavy use.

Also, check inlet screens. These sit where paint enters the sprayer. A clean screen keeps debris out and protects the system.

4. Pumps and Seals

The pump is the core of your sprayer. It builds pressure and moves paint. Over time, seals inside the pump wear down. This reduces pressure and performance.

You can often replace just the seals instead of the full pump. This repair is more affordable and extends the machine’s life.

Why Choose Genuine Replacement Parts

Using original parts from your sprayer's brand is always a smart move. Here’s why:

Perfect fit: Designed to match your exact model.

Reliable quality: Meets safety and performance standards.

Warranty safety: Keeps your equipment under valid warranty.

Longer lifespan: OEM parts often last longer than generic ones.

Generic parts may seem cheaper, but they can cause problems in the long run. Always double-check compatibility before buying.

Replace or Repair: What Makes Sense?

Sometimes, it’s hard to decide whether to replace parts or buy a new sprayer. Here are a few tips:

Age of the unit: If the sprayer is over 5–7 years old and breaking often, it may be time for a new one.

Cost of parts: If repairs cost more than 50% of a new sprayer, upgrading could be smarter.

Project size: For large or frequent jobs, investing in repairs may offer more value.

Performance drop: If the sprayer struggles even after replacing parts, a full upgrade may be the answer.

Maintenance Tips to Extend Lifespan

You can avoid early replacements with simple habits. Here’s how to keep your sprayer working well:

Clean after each use: Flush out paint and residue with water or cleaning fluid.

Check for clogs: Inspect the tip and filter regularly.

Store it right: Keep your sprayer in a dry, temperature-controlled place.

Oil moving parts: This reduces wear on seals and pistons.

Run test sprays: Check the pattern before starting a job.

Regular care keeps your sprayer strong and helps spot problems early.

Where to Find Quality Replacement Parts

There are many sources for spray equipment parts. For best results:

Buy from official brand stores or their websites.

Look for authorized dealers near you.

Use trusted online platforms with clear return policies.

Always verify model numbers before ordering.

A good dealer can guide you to the right parts and offer installation tips if needed.

Final Thoughts

Revitalizing your spray equipment doesn’t have to be costly or complicated. With the right replacement components, your titan elite sprayer parts can feel brand new again. You don’t need to toss it out at the first sign of trouble.

Listen to your equipment. If the spray seems off, it may just need a new tip or hose. If the pressure fades, check the pump seals. A few small changes can lead to big improvements.

Taking action today saves time and frustration tomorrow. So give your sprayer a second life—with smart replacements and regular care, it's ready to perform like a pro.