Introduction to Metal Machining Parts

Metal machining plays a vital role in various industries, including aerospace, automotive, and medical sectors. High-quality machining parts ensure precision, durability, and efficiency in manufacturing processes. Finding a trusted metal machining parts manufacturer is key to maintaining superior production standards.

Key Factors in Choosing a Metal Machining Parts Manufacturer

Selecting the right manufacturer requires assessing several critical factors. These include production capabilities, material quality, precision standards, and customization options. A reliable supplier should offer state-of-the-art CNC machining, strict quality control, and innovative production techniques.

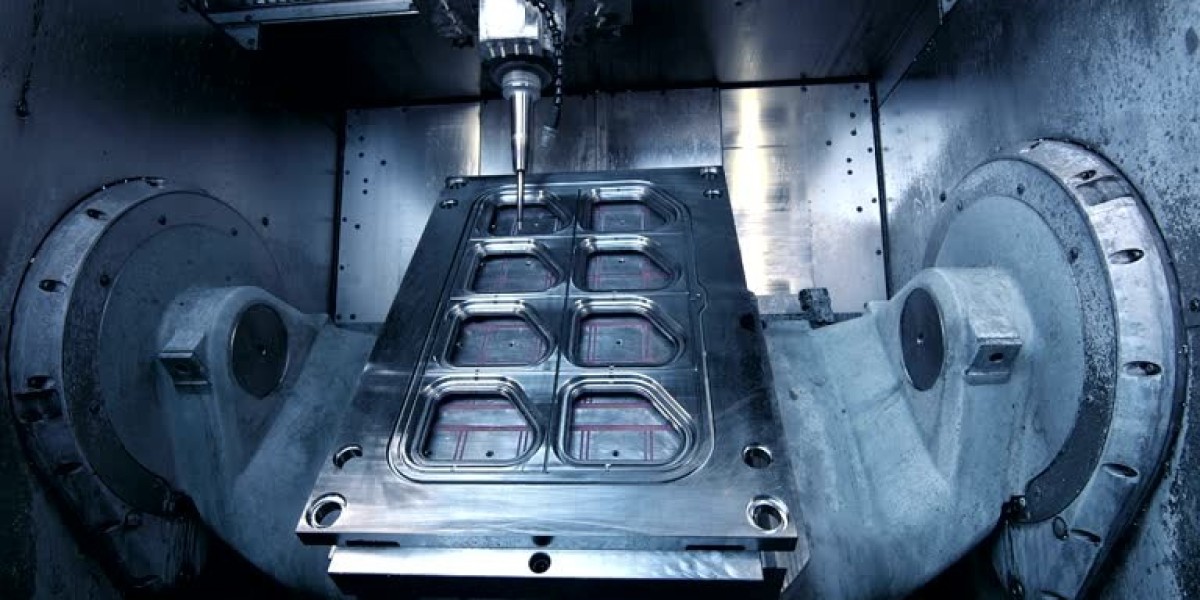

Advanced CNC Machining Technology

The best manufacturers use advanced CNC (Computer Numerical Control) machines. These machines offer unparalleled precision and consistency. Multi-axis CNC machining ensures complex parts meet exact specifications. Manufacturers investing in modern technology guarantee superior product quality and faster production times.

Quality Control and Assurance Standards

A reputable manufacturer implements strict quality control measures. Compliance with ISO 9001 and other industry certifications ensures consistency. Regular inspections, automated testing, and adherence to strict tolerances are essential to maintaining quality. High-standard machining reduces defects and enhances product reliability.

Material Selection for Superior Performance

Material selection impacts the durability and functionality of metal parts. Leading manufacturers offer materials such as stainless steel, aluminum, titanium, and brass. The right material choice depends on factors like corrosion resistance, strength, and thermal stability. Top manufacturers provide expert guidance on material selection for specific applications.

Customization and Precision Engineering

Custom machining solutions cater to industry-specific needs. Precision engineering ensures components fit seamlessly into complex assemblies. Manufacturers with design support, prototyping, and CAD/CAM technology offer unmatched customization. Tailored solutions enhance performance and efficiency in industrial applications.

Innovative Manufacturing Techniques

Innovation drives the machining industry forward. Techniques such as 3D printing, laser cutting, and automated assembly improve accuracy. Continuous investment in research and development helps manufacturers stay ahead. Companies focusing on innovation deliver high-performance machining parts with enhanced features.

Cost-Effective Production Without Quality Compromise

Balancing cost and quality is crucial in metal machining. Leading manufacturers optimize production efficiency to minimize waste and reduce costs. Bulk manufacturing, lean production methods, and automated machining lower expenses. Customers benefit from cost-effective solutions without compromising quality.

Sustainable Manufacturing Practices

Environmental responsibility is a growing concern in the machining industry. Top manufacturers adopt sustainable practices, including waste reduction, energy-efficient machining, and recycling programs. Eco-friendly production methods align with global sustainability standards and enhance brand reputation.

Industry Applications of Metal Machining Parts

Machined metal parts serve a wide range of industries. In aerospace, precision components ensure flight safety and performance. The automotive sector relies on machined parts for engines, transmissions, and suspension systems. Medical device manufacturing requires high-precision components for surgical tools and implants. Industrial machinery and electronics also depend on metal machining for durability and functionality.

Why Choose a Leading Metal Machining Parts Manufacturer?

Working with a top manufacturer ensures high-quality products, cutting-edge technology, and reliable customer support. Trusted manufacturers provide fast turnaround times, strict quality assurance, and competitive pricing. Investing in a reputable supplier leads to long-term success and operational efficiency.

Conclusion

Finding a top brass nozzles manufacturer requires evaluating quality, technology, and industry expertise. Advanced CNC machining, stringent quality control, and innovative production methods set the best suppliers apart. Partnering with a trusted manufacturer ensures precision, durability, and cost-effective solutions for various industries.