Transformer oil plays a vital role in ensuring the efficiency and longevity of transformers. It acts as both an insulator and a coolant, safeguarding the transformer from electrical and thermal stresses. A crucial parameter used to evaluate the quality of transformer oil is the Breakdown Voltage (BDV) test. This article will discuss the importance of the transformer oil bdv test, how it works, and why it is critical for transformer maintenance.

What is the Transformer Oil BDV Test?

The bdv for transformer oil is a measure of the oil’s ability to withstand electrical stress without breaking down. When transformer oil deteriorates due to impurities such as moisture, sludge, or dissolved gases, its dielectric strength decreases, posing a risk of insulation failure. The BDV test evaluates the oil's insulating properties and determines if it is safe for use in transformers.

Importance of the Transformer Oil BDV Test

Ensuring Transformer Safety

Transformers handle high voltages, making insulation critical. Low BDV levels in transformer oil indicate compromised insulation, increasing the likelihood of electrical breakdowns and transformer failure. Regular testing ensures the oil maintains adequate dielectric strength.Preventing Transformer Damage

Impurities such as water and particulate matter can lower the BDV of transformer oil. If not detected early, these contaminants can lead to overheating, short circuits, and costly repairs. The transformer oil bdv test identifies these issues before they escalate.Extending Transformer Lifespan

Transformers are expensive assets. By ensuring the oil's quality through regular BDV testing, operators can reduce wear and tear, improving the transformer’s operational lifespan.Compliance with Standards

Various industry standards, such as IEC 60156, define acceptable BDV levels for transformer oil. Regular testing ensures compliance with these standards, guaranteeing the transformer operates safely and efficiently.

How the Transformer Oil BDV Test is Performed

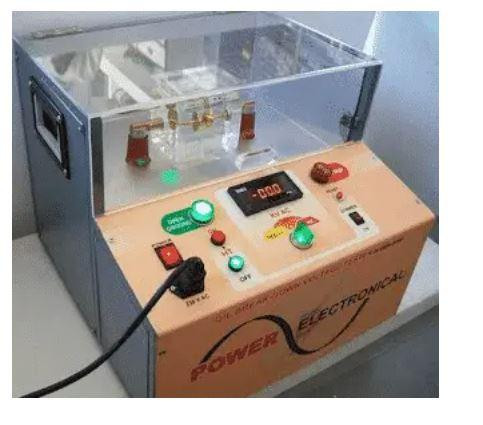

The transformer oil BDV test is a straightforward procedure performed using a BDV testing kit. The steps involved are:

Sampling the Oil

A representative sample of transformer oil is collected from the transformer. It is crucial to avoid contamination during sampling to ensure accurate results.Preparing the Test Equipment

The BDV testing kit consists of a test vessel with two electrodes placed at a specified distance, typically 2.5 mm or 4 mm. The kit is cleaned thoroughly to prevent external contaminants from affecting the results.Performing the Test

- The transformer oil sample is poured into the test vessel.

- A voltage is gradually applied to the electrodes at a controlled rate (approximately 2 kV per second).

- The voltage is increased until the oil breaks down, indicated by a spark between the electrodes.

- The breakdown voltage is noted, and the test is repeated multiple times to obtain an average value.

Interpreting the Results

The average BDV value is compared against industry standards. A typical BDV for transformer oil should be above 30 kV. Lower values indicate contamination or degradation, requiring oil purification or replacement.

Factors Affecting BDV for Transformer Oil

Several factors influence the BDV of transformer oil:

Moisture Content

Even trace amounts of water significantly reduce the oil's dielectric strength. Moisture can enter the oil through leaks or condensation.Particulate Contamination

Dirt, sludge, or metal particles in the oil create conductive paths, lowering the BDV. Regular filtration can help mitigate this issue.Temperature

High temperatures can cause oil degradation, forming acids and sludge that impact BDV.Oxidation

Prolonged exposure to air causes oxidation, which generates sludge and decreases the oil’s insulating properties.

Improving Transformer Oil BDV

If the BDV test results indicate low dielectric strength, steps must be taken to restore the oil’s quality:

Oil Filtration

Filtration removes particulate matter and improves BDV. Advanced filtration systems can also remove dissolved gases and moisture.Oil Regeneration

Regeneration processes use chemical and thermal treatments to restore the oil's original properties, including BDV.Oil Replacement

In cases where contamination is severe, replacing the transformer oil is the best solution to ensure safe operation.

You Can Also Visit Us : -

bdv value of 11kv transformer oil

Conclusion

The transformer oil BDV test is an essential maintenance practice that ensures the reliability and safety of transformers. By measuring the dielectric strength of transformer oil, the BDV test identifies potential issues such as contamination or degradation before they lead to costly failures. Regular testing, combined with proper maintenance like filtration and regeneration, helps maintain high BDV values, ensuring the transformer operates efficiently for years to come.