When it comes to manufacturing and production processes, assembly is a crucial step. Whether you're building a product from scratch or assembling components, the method used can significantly impact the efficiency, accuracy, and overall quality of the product. Two common methods for assembly are assembly fixtures and manual assembly. In this article, we’ll break down the differences between these two methods, exploring their benefits, challenges, and which is best suited for various industries.

If you’re looking to improve the efficiency of your assembly line, a great option to consider is the PCF fixture. Let’s dive deeper into understanding both assembly methods and how they compare.

1. What Are Assembly Fixtures?

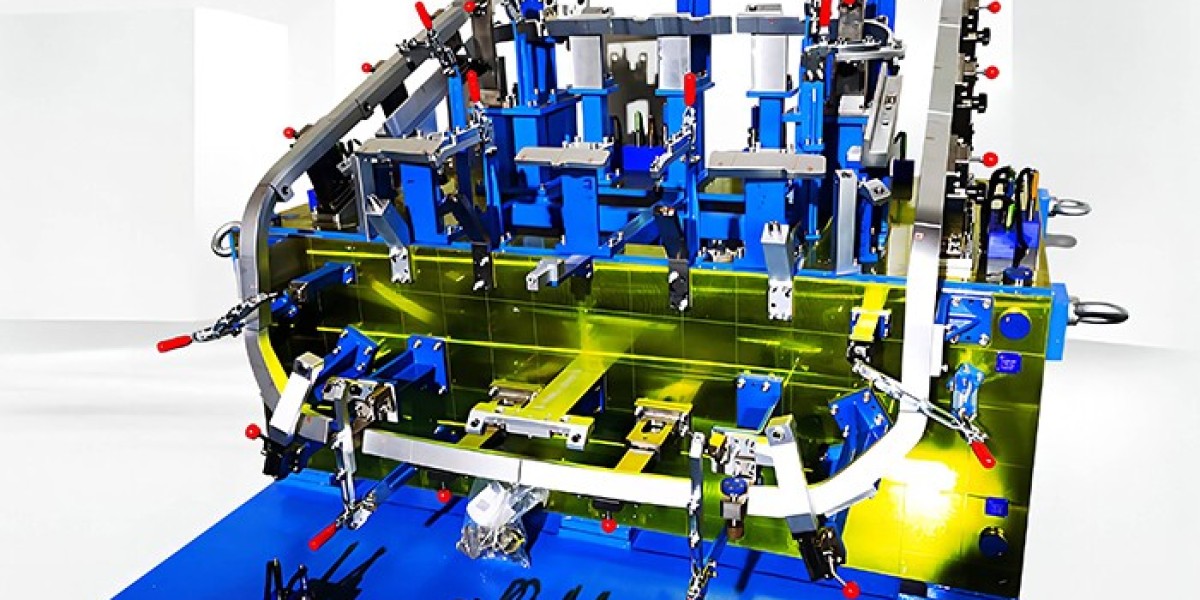

Assembly fixtures are specialized tools used to hold, position, and secure parts during the assembly process. These fixtures are designed to ensure that parts are consistently aligned and placed with precision. They are often used in industries where high accuracy and speed are required, such as automotive manufacturing, electronics, and aerospace.

Fixtures come in various forms, such as manual, automated, or semi-automated, and can be customized to fit specific products or production needs. The main advantage of using fixtures is that they provide a stable and secure base for parts, minimizing the risk of errors or defects in the final product.

2. What Is Manual Assembly?

Manual assembly, on the other hand, refers to the process where workers assemble products by hand. This can involve using simple tools like screwdrivers, wrenches, or hammers, or it could involve more complex tasks like soldering or welding. Manual assembly is often seen in industries where custom work or small production runs are required.

While manual assembly provides flexibility and allows for customization, it is highly dependent on the skill of the workers. Errors in manual assembly can lead to quality issues, and the process tends to be slower than when using assembly fixtures.

3. Key Differences Between Assembly Fixtures and Manual Assembly

Let’s now compare the two assembly methods in detail by looking at their key differences.

3.1 Speed and Efficiency

Assembly fixtures are designed to enhance speed and efficiency. Because fixtures secure parts in place, workers can focus on quickly assembling components without the need to constantly reposition items. Fixtures are ideal for high-volume production because they reduce the time spent on each assembly task.

In contrast, manual assembly is much slower. While it offers flexibility for smaller or custom jobs, it can’t match the speed of automated systems. Workers need to handle each part individually, which takes more time and can result in slower production rates.

3.2 Accuracy and Precision

When it comes to accuracy, assembly fixtures have the upper hand. These fixtures are designed to ensure that parts are aligned correctly, reducing the chances of human error. Whether it’s a small component or a complex assembly, fixtures allow for more consistent results.

Manual assembly, however, is prone to human error. Even the most experienced workers can make mistakes, such as misaligning parts or incorrectly attaching components. Over time, these errors can accumulate and affect the overall quality of the product.

3.3 Worker Safety

In terms of safety, both methods have their pros and cons. Assembly fixtures can reduce the risk of accidents by ensuring that parts are secure and stable during the assembly process. This minimizes the chances of parts shifting unexpectedly or workers being injured by moving components.

Manual assembly, on the other hand, can be riskier, especially when workers are handling sharp tools or heavy parts. Additionally, the repetitive nature of manual assembly can lead to physical strain and injuries over time, such as carpal tunnel syndrome or back problems.

3.4 Flexibility and Customization

Manual assembly is far more flexible than assembly fixtures. Workers can easily adapt to custom tasks, small batches, or one-off productions. If you’re working on a unique product or need to make last-minute adjustments, manual assembly allows for more adaptability.

Assembly fixtures, while efficient, are typically designed for specific tasks or products. They can be modified or adjusted, but they may not be as versatile as manual assembly for highly custom or varied jobs.

4. Cost Considerations: Initial Investment vs. Long-Term Savings

When it comes to cost, manual assembly has a lower initial investment. You don’t need to purchase specialized tools or equipment, and you can rely on the skills of your workers. However, as production volumes increase, the long-term costs can add up. More workers may be needed to keep up with demand, and errors in manual assembly can lead to additional costs associated with rework or waste.

On the other hand, assembly fixtures require a significant upfront investment in tooling and setup. However, the cost of fixtures can be recouped in the long run due to increased productivity, fewer errors, and reduced labor costs. Fixtures also provide a more consistent assembly process, which can lead to higher product quality and fewer returns.

5. Types of Assembly Fixtures

There are various types of assembly fixtures, depending on the industry and the type of product being assembled. Some common types include:

- Manual Fixtures: These require the worker to position parts manually but offer guidance and alignment to ensure accuracy.

- Automated Fixtures: These fixtures are integrated with robotic systems to automate part handling and assembly, reducing the need for human intervention.

- Semi-Automated Fixtures: These fixtures combine manual and automated components, allowing workers to assemble parts with assistance from automated systems.

Each type of fixture has its own benefits, but in general, automated and semi-automated fixtures offer the highest levels of speed and efficiency.

6. When to Use Assembly Fixtures

Assembly fixtures are best suited for high-volume production lines where speed and accuracy are critical. Industries like automotive manufacturing, consumer electronics, and medical device production rely heavily on fixtures to maintain consistent product quality while increasing throughput.

If your company deals with large quantities of the same product, fixtures can help streamline the assembly process and reduce labor costs. Additionally, fixtures are ideal for complex assemblies that require high precision and consistency.

7. When to Choose Manual Assembly

Manual assembly works well in situations where flexibility is key. For smaller production runs, custom orders, or unique products, manual assembly can provide the necessary adaptability. It’s also a good choice when dealing with products that require a high level of craftsmanship or custom adjustments.

If you’re working with small quantities or intricate products that need frequent design changes, manual assembly may be the better option. While it’s slower, it offers more hands-on control and can be adjusted more easily.

8. Hybrid Approach: Combining Both Methods

In many modern production environments, manufacturers are adopting a hybrid approach, combining both assembly fixtures and manual assembly. This approach allows businesses to take advantage of the efficiency of fixtures while maintaining the flexibility of manual assembly.

For example, workers may use fixtures to hold parts in place and ensure alignment, but they may still handle the assembly of certain components manually, especially when customization is required. This combination provides the best of both worlds—speed, accuracy, and adaptability.

9. Quality Control in Assembly Fixtures and Manual Assembly

Quality control is crucial in both assembly methods, but fixtures have a clear advantage when it comes to consistency. Because fixtures ensure that parts are aligned and placed correctly, they help maintain the highest quality standards.

In manual assembly, quality control often relies on the skill of the workers. While experienced workers can produce high-quality products, there’s always a risk of human error. Having strong quality control procedures in place is essential to catch any mistakes before they affect the final product.

10. The Future of Assembly: Innovations and Trends

The future of assembly is undoubtedly heading towards greater automation and integration. As technology advances, we can expect to see more sophisticated assembly fixtures that combine robotics, AI, and smart technologies to enhance the process further. These innovations will make assembly lines faster, more accurate, and more flexible.

Manual assembly, while still important, will likely take a back seat as automation becomes more widespread. However, for niche industries or highly customized products, manual assembly will continue to play a role.

Conclusion

In the debate between assembly fixtures and manual assembly, both methods have their strengths and weaknesses. Assembly fixtures excel in terms of speed, accuracy, and long-term cost savings, making them ideal for high-volume production. Manual assembly, while slower and more prone to errors, offers flexibility and adaptability for custom jobs and smaller runs.

Ultimately, the choice between the two methods depends on your business’s specific needs. For industries where efficiency, precision, and high-volume output are crucial, assembly fixtures are the way to go. However, for smaller, custom tasks, manual assembly may be the better option.