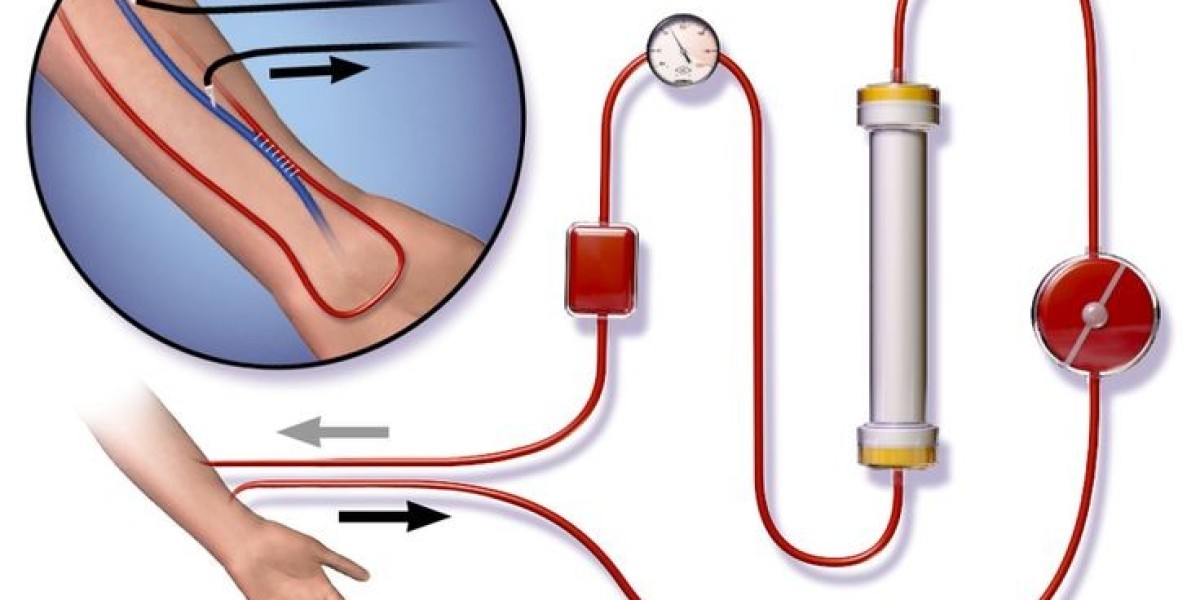

Polytetrafluoroethylene (PTFE) is one of the most widely used materials in hemodialysis vascular grafts. PTFE has garnered significant attention due to its biocompatibility, durability, and low thrombogenicity, meaning it has a lower chance of causing blood clots. These properties make PTFE an excellent choice for vascular grafts, especially in patients with end-stage renal disease (ESRD) who require frequent hemodialysis access.

Furthermore, PTFE grafts are resistant to infection and have high long-term patency, meaning they remain open and functional for extended periods, reducing the need for frequent interventions. According to recent studies, PTFE grafts have shown a reduced infection rate, which is critical in hemodialysis patients prone to infections due to repeated vascular access. Additionally, the pliability of PTFE makes it easier for surgeons to handle during implantation, further improving patient outcomes

.

2. How Can the Risk of Infection Be Minimized in Dialysis Grafts?

Infection prevention remains a top priority in hemodialysis vascular grafts, especially given the frequency with which these grafts are accessed. Recent advancements have focused on coated grafts, which utilize antimicrobial agents to reduce the risk of bacterial colonization on the graft material. One such development is antibiotic-coated PTFE grafts, which have been shown to lower infection rates significantly, extending the lifespan of the graft and reducing hospitalizations due to infection complications

.

In addition, innovations in bio-engineered grafts have introduced grafts with self-healing capabilities and improved biological integration. These newer grafts are designed to mimic natural vascular tissues, further decreasing the chances of infection while promoting better healing and compatibility within the patient’s vascular system.

3. What Are the Newest Developments in Hemodialysis Vascular Graft Technology?

Hemodialysis vascular graft technology has evolved rapidly, with companies like Medtronic, Getinge, and CryoLife leading the way in innovation. Recent advances focus on improving graft longevity, reducing infection risks, and enhancing biocompatibility. One of the most notable innovations is self-healing grafts, which are engineered to respond to damage by regenerating tissues, significantly extending the life of the graft and reducing the need for repeat surgeries

.

Another breakthrough is the use of bioresorbable materials, which dissolve naturally in the body once their job is done. These grafts are used temporarily, reducing long-term complications and offering a more natural healing process. For example, Xeltis’ aXess vascular graft is a promising innovation that has shown excellent patency rates and a 0% infection rate in clinical trials

.

4. Which Materials Are Most Commonly Used in Vascular Grafts for Kidney Dialysis?

Materials used in vascular grafts for hemodialysis are carefully chosen to balance durability, flexibility, and biocompatibility. The most common materials include PTFE (polytetrafluoroethylene) and polyester, both synthetic materials that offer superior handling properties for surgeons and durability for patients. PTFE, as discussed, dominates the market due to its superior characteristics like infection resistance and long-term graft patency

.

In addition to synthetic materials, biological grafts made from human or bovine tissues are also used in certain cases. These biological grafts offer better integration with the patient’s body, though they may be more prone to infection compared to their synthetic counterparts. However, biological grafts have seen advancements as well, particularly with the incorporation of biological scaffolds that help in tissue regeneration and graft acceptance

.

Top Companies Driving Innovation in Hemodialysis Vascular Grafts

- Medtronic: Continues to pioneer advancements in vascular access grafts, particularly with its biologically coated grafts that aim to reduce thrombosis and infection rates. Their partnership with DaVita to form a dedicated kidney care company emphasizes their commitment to innovation in the field

- Getinge: Through their Atrium Medical division, Getinge is developing interventional vascular solutions, including vascular grafts that focus on improving durability and reducing complications in hemodialysis patients

- CryoLife: This company is well-known for its focus on biological vascular grafts and tissue-based solutions, which promote better healing and integration in hemodialysis patients

- W. L. Gore & Associates: The creators of Gore-Tex, have developed vascular grafts using the material for high-performance, long-lasting solutions, contributing to its widespread use in clinical settings

These key players continue to drive the market forward through mergers, acquisitions, and clinical trials, all aimed at improving patient outcomes in the hemodialysis vascular graft space.

For more info

Related report

primary care physician marketblood gas and electrolyte analyzer marketcancer photodynamic therapy market