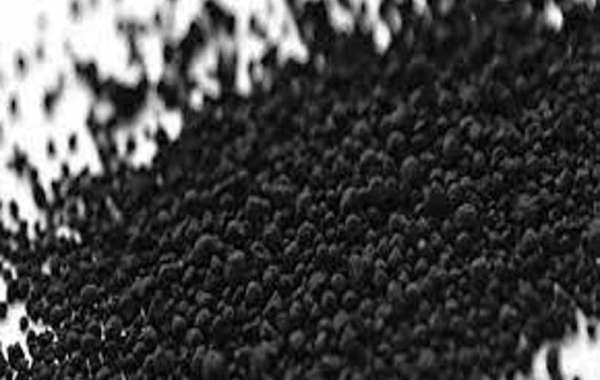

Recovered carbon black is produced from pyrolysis of waste rubber tires. It is used in production of new tires, rubber products, insulating mats, wires and cables, toners and colors. It provides cost savings over virgin carbon black. It helps in diverting waste tires from landfills and incineration thereby reducing environmental pollution.

The Recovered Carbon Black market is estimated to be valued at US$ 279.52 Mn in 2023 and is expected to exhibit a CAGR of 32. % over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Dynamics:

Recovered carbon black market is driven by rising environmental concerns regarding disposal of waste tires. Carbon black production from waste tires helps in reducing carbon footprint. It is estimated that around 1 million tons of recovered carbon black can be produced annually by recycling nearly 270 million scrap tires globally generated each year. Additionally, recovered carbon black has equal quality and performance as compared to virgin carbon black at 20-30% lower price which makes it attractive option for various industrial applications. However, availability of substitutes of carbon black like silica can hamper the market growth over the forecast period.

SWOT Analysis

Strength: Recovered carbon black from scrap tire pyrolysis is considered an environment-friendly alternative to conventional carbon black. It has identical physical and chemical properties as conventional carbon black. The end products from recovered carbon black such as tires and rubber products are 100% recyclable. The process allows effective utilization of waste tires thereby promoting circular economy.

Weakness: High initial investments are required to set up recycling facilities for scrap tire pyrolysis. stringent environmental regulations pertaining to air pollution emissions from pyrolysis plants pose operational challenges.

Opportunity: Growing automotive industry and increasing vehicular traffic is leading to surge in scrap tire volumes providing steady feedstock supply. Stringent regulations globally regarding end-of-life tire management is driving demand for recovered carbon black.

Threats: Availability of cheaper substitutes such as conventional carbon black limits the market growth of recovered carbon black. Volatility in raw material prices impacts the profit margins of recovered carbon black producers.

Key Takeaways

The global recovered carbon black market is expected to witness high growth, exhibiting CAGR of 32.% over the forecast period, due to increasing environmental regulations regarding waste tire management and recyclability across markets. Stringent policies mandate the effective recycling and reuse of end-of-life tires.

Regional analysis: North America dominated the global recovered carbon black market in 2020 and accounted for over 30% of the total demand. Presence of largest scrap tire volumes as well as established producers such as Pyrolyx AG in the region drives the recovered carbon black market. Asia Pacific is predicted to witness fastest growth on account of burgeoning automotive industry, rising vehicles ownership and supportive government policies regarding circular economy in countries such as China, India and Indonesia.

Key players operating in the recovered carbon black market are Pyrolyx AG,SR2O Holdings,Alpha Carbone,Scandinavian Enviro System AB,Integrated Resource Recovery,Delta-Energy Group,Bolder Industries,Black Bear Carbon B.V,DVA Renewable Energy JSC,Others. Pyrolyx AG is a pioneering producer of recovered carbon black using patented Tyre Pyrolysis Technology. The company has production facilities across Germany and the U.S.

Søg

- Friendly Websites www.wsisw.com www.bybit.com www.temu.com www.ebay.com www.adsy.com www.iherb.com www.whmcs.com www.secsers.com www.cambly.com www.binance.com www.displate.com www.magenet.com www.gainrock.com www.seoclerks.com www.aliexpress.com www.freelancer.com www.rankranger.com www.wehaveoffer.com www.qrmenutable.com www.coinpayments.net www.linksmanagement.com

Populære opslag