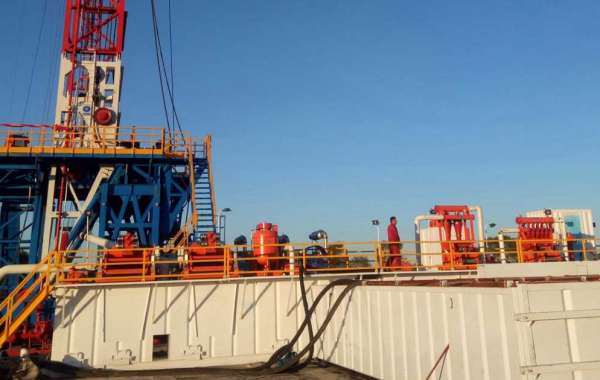

In the intricate world of drilling operations within the oil and gas industry, the efficient management of drilling fluids and the removal of solids are paramount. This is where solids control equipment plays a pivotal role. This article delves into the significance, components, and functionalities of solids control equipment, exploring how these vital systems contribute to the success and sustainability of drilling endeavors.

Introduction to Solids Control Equipment

Solids control equipment is an integral part of the drilling process in the oil and gas industry, designed to manage drilling fluid properties and remove undesirable solids. The primary goal is to maintain the drilling fluid in optimal condition, ensuring that it can effectively carry out its functions in cooling, lubrication, and the removal of drill cuttings.

Key Components of Solids Control Equipment

Shale Shakers:

Shale shakers are the frontline warriors in solids control. They use a vibrating screen to separate large drill cuttings from the drilling fluid. The vibrating motion allows the fluid to pass through the screen while the cuttings are discarded, preventing them from entering the mud system.

Desanders:

Desanders are hydrocyclone-based units that target larger particles in the drilling fluid. Positioned downstream of the shale shakers, desanders remove sand and silt, further refining the drilling fluid.

Desilters:

Similar to desanders, desilters use hydrocyclones to target smaller particles in the mud. Placed downstream of desanders, they enhance the purification process by capturing finer solids that may have passed through the previous stages.

Decanting Centrifuges:

Decanting centrifuges are high-speed rotating machines that use centrifugal force to separate solids from the drilling fluid. They are effective in handling ultra-fine solids and contribute to the overall clarification of the mud.

Mud Agitators:

Mud agitators are mechanical devices that keep the drilling fluid in a homogeneous state by preventing solids from settling at the bottom of the mud tanks. They ensure the consistency of the mud properties throughout the drilling process.

Mud Cleaners:

Mud cleaners combine the functionalities of shale shakers, desanders, and desilters in a single unit. They efficiently remove both large and small particles from the drilling fluid, streamlining the solids control process.

Significance of Solids Control in Drilling Operations

Enhanced Drilling Fluid Properties:

Solids control equipment plays a crucial role in preserving the integrity of drilling fluids. By removing unwanted solids, the equipment ensures that the mud maintains its required properties, including viscosity, density, and lubrication.

Extended Equipment Lifespan:

Efficient solids control contributes to the longevity of drilling equipment. Reduced abrasive wear on pumps, pipes, and other components results in less maintenance and replacement, leading to cost savings for drilling operations.

Improved Drilling Performance:

The removal of solids enhances the drilling performance by reducing the risk of equipment failure and avoiding issues such as stuck pipes, decreased penetration rates, and overall operational inefficiencies.

Environmental Compliance:

Solids control equipment plays a role in environmental stewardship by preventing the discharge of contaminated drilling fluids into the environment. Compliance with environmental regulations is essential for sustainable and responsible drilling practices.

Innovation in Solids Control Technology

The oil and gas industry continuously invests in research and development to enhance the efficiency and effectiveness of solids control equipment. Innovations in technology aim to address industry challenges, improve overall performance, and contribute to sustainable drilling practices.

Smart Sensing and Automation:

Integrating smart sensors and automation technologies allows for real-time monitoring of drilling fluid conditions. This enables immediate adjustments to the solids control process, optimizing performance and minimizing downtime.

High-Capacity Centrifuges:

Advancements in centrifuge technology have led to the development of high-capacity centrifuges that can handle larger volumes of drilling fluid while maintaining effective solids separation. This improves overall processing efficiency.

Environmentally Friendly Practices:

Sustainable drilling practices are a growing focus in the industry. Solids control equipment manufacturers are exploring ways to minimize waste generation, recycle drilling fluids, and reduce the environmental footprint of drilling operations.

Challenges and Considerations in Solids Control

While solids control equipment is instrumental in maintaining drilling fluid quality, certain challenges and considerations warrant attention:

Variable Drilling Conditions:

Drilling conditions can vary significantly from one project to another. Solids control systems must be adaptable to different types of formations, drilling fluids, and operational requirements.

Maintenance and Downtime:

Regular maintenance of solids control equipment is essential to ensure consistent performance. However, the challenge lies in minimizing downtime during maintenance activities to optimize operational efficiency.

Cost Considerations:

The initial investment in high-quality solids control equipment can be significant. However, the long-term benefits, including reduced operational costs and extended equipment lifespan, often outweigh the upfront expenses.

Conclusion: Optimizing Drilling Operations with Solids Control

In conclusion, solids control equipment stands as a cornerstone in the oil and gas industry, ensuring the efficiency, sustainability, and environmental responsibility of drilling operations. The continuous evolution of technology in solids control reflects the industry's commitment to enhancing performance and addressing challenges. As drilling activities continue to advance, the role of solids control equipment remains indispensable in fostering efficient, safe, and environmentally conscious practices within the dynamic realm of oil and gas exploration.