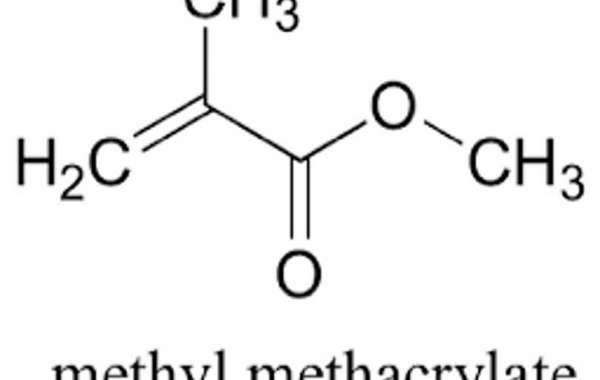

Methyl methacrylate (MMA) is a colorless, volatile liquid with a characteristic pleasant acetone-like odor. It is used in the production of homo-polymers and copolymers. MMA finds major applications in the manufacturing of polymethyl methacrylate (PMMA) which is used to produce acrylic sheets and resins used in signs, construction, automotive and aerospace industries.

The Methyl Methacrylate market is estimated to be valued at US$ 7,510.7 Mn in 2023 and is expected to exhibit a CAGR of 4.9% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Dynamics:

The global methyl methacrylate market is primarily driven by increasing demand from the automotive and construction industries. MMA based PMMA sheets and resins are largely used in automotive front-ends, lighting, side panels, windows and sun-roofs. Growth in automotive production across major economies such as China, India and Germany is fueling demand for MMA. Additionally, increasing spending on infrastructure and residential construction worldwide is propelling consumption of MMA based acrylic sheets and polymers in various glazing, cladding, signage and decorative applications. Furthermore, MMA's ability to provide excellent optical clarity, weather resistance and good dimensional stability drives its preference over other thermoplastics. However, health issues associated with MMA exposure and volatile crude oil prices pose challenges to market growth.

SWOT Analysis

Strength: Methyl methacrylate has wide applications in various industries such as construction, automotive etc which drives its demand. It is cost effective to produce and transport. Continuous technological advancements have improved its production process.

Weakness: Strict environmental norms regarding its production and disposal can increase costs. Volatility in raw material prices impacts the overall costs. Exposure to carcinogenic substances during production is a health risk.

Opportunity: Rising applications in new industries such as electronics and medical offer new opportunities for growth. Developing countries offer huge untapped market potential. Alternative production methods can help overcome weaknesses.

Threats: Presence of substitute products poses competition in the market. Economic slowdowns can impact the demand adversely. Stringent safety regulations regarding its handling and transport are a challenge.