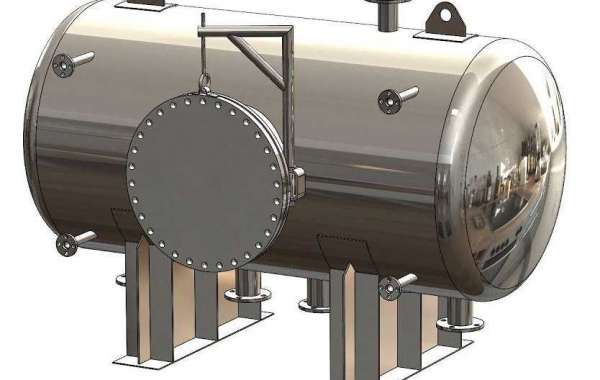

S/s tanks or surplus Stainless steel tanks are versatile and popular for water storage. They are hygienic and durable, and offer superior corrosion resistance. They are also suitable for pharmaceutical and water treatment applications.

The right metal fabricator can fabricate a tank to fit any need. They can create a mounting system to secure the tank during transportation and provide accessories like dip charts and level gauges. S/s tanks or surplus stainless steel tanks are the best to use . Stainless steel tanks near me at surplus tanks . Buy stainless steel tanks at surplusrecord . Used stainless steel tanks for sale are also at surplus stainless steel tanks

Single wall

Single-wall stainless steel tanks can be fabricated from a number of different grades, each with specific alloy formations. The alloy formations dictate the tank’s corrosion resistance. The most commonly used stainless steels are 304 and 316. Stainless steel 304 typically contains 18-20% chromium and 8-12% nickel. Higher chromium content creates stronger corrosion resistance. 316 contains 2% molybdenum, increasing the corrosion resistance even further.

These tanks are the most popular choice for storing fuel and oil. Their sturdy construction prevents fuel from leaking out of the tank and contaminating soil around it. They can be used to store propane, kerosene, and diesel. They also meet EPA requirements for spill containment. S/s tanks or surplus stainless steel tanks are the best to use . Stainless steel tanks near me at surplus tanks . Buy stainless steel tanks at surplusrecord . Used stainless steel tanks for sale are also at surplus stainless steel tanks

Medical equipment requires a highly hygienic environment. Stainless steel tanks are ideal for storage because they do not absorb bacteria and can be easily cleaned.

S/s tanks or surplus Stainless steel tanks are also suited to process fluids that require high temperatures. They are also used to store compressed air for manufacturing and industrial purposes. They feature a lining that protects the stainless steel from corrosive air and moisture.

Stainless steel cladded carbon steel tanks are fabricated by pressing and heating the two metals together to form a metallurgical bond. Stainless steel cladding prevents corrosion by forming a thin oxide layer that protects the carbon steel beneath it. The cladding can be bonded on one side (single-side cladding) or both sides of the tank (double-side cladding). Depending on the location, some double-walled tanks have insulation between their walls to protect the product from changes in ambient temperature.

Double wall

In stainless steel double wall tanks, the outer walls are spot- or plug-welded to the inner wall. This makes it stronger than jacketed tanks, and allows thinner sheets to be used. The welded seams are insulated, which reduces heat loss and keeps the contents of the tank cool. This is important for air receivers and other compressed air systems in manufacturing plants and industrial facilities that operate at high pressures.

The chromium content of stainless steel provides excellent corrosion resistance. This is because it creates a thin oxide layer on the surface of the metal, which acts as a passive barrier against the elements. The corrosion-resistant properties of stainless steel are improved by other alloying elements, including nickel and manganese.

Stainless steel is a versatile material for tanks because of its good corrosion resistance, low weight, and high strength. It is available in many different grades, each with its own unique properties. Grade 304 is the most popular, and it is a good choice for most applications. It contains 18-20% chromium and 8-12% nickel, and it is cost-effective. Grade 316 offers better corrosion resistance, but it is more expensive than 304.

Some s/s tanks or surplus tanks are built with an inner layer made of stainless steel and an outer shell of carbon or other steel. This combination is ideal for storing adblue, an aqueous urea solution. It is a safe and environmentally-friendly alternative to diesel fuel. S/s tanks or surplus stainless steel tanks are the best to use . Stainless steel tanks near me at surplus tanks . Buy stainless steel tanks at surplusrecord . Used stainless steel tanks for sale are also at surplus stainless steel tanks

Jacketed

S/s tanks or surplus Stainless steel tanks with jackets are used in brewing and fermentation applications where temperature control is crucial. They are available in a variety of sizes and designs to accommodate your unique needs. Using a jacketed tank allows you to maintain precise temperatures and avoid skunking your product. They are also a good option for storing a large volume of liquids. At Bid on Equipment, you can find previously owned jacketed tanks at reasonable prices to meet your budget.

When choosing a storage tank, consider the volume of chemicals it will hold and your facility’s space requirements. You should also determine the amount of agitation needed to mix the chemicals. This will help you determine the size of your stainless tanks near me. You should also choose a s/s tanks or surplus stainless steel tank that meets industry safety and environmental guidelines.

The chromium content in stainless steel provides corrosion resistance, protecting the stored chemical from degradation. It also helps protect the tank from moisture and rust. The chromium content in the metal is also able to resist high-temperature oxidation, making it a great choice for use in food and pharmaceutical industries.

S/s tanks or surplus Stainless steel tanks are highly durable and have a long lifespan. They are not susceptible to rust or corrosion, so they can be used for long periods of time without damaging them. Moreover, they can be cleaned quickly and easily.

Customized

S/s tanks or surplus Stainless steel tanks can be customized to suit the needs of specific applications and industries. They are used to store all kinds of materials and substances, including liquids, gases, and solids. They can also be designed to withstand harsh environmental conditions and resist corrosion. However, they can have limitations, depending on the type of materials stored and how they are handled.

To ensure safety and compliance, tank manufacturers must adhere to professional standards and regulations. These may vary by industry and are often established in conjunction with governing bodies like the American Petroleum Institute. In addition, the manufacturer must be able to design and fabricate the tank using modern techniques and materials. This includes welding and corrosion-resistant coatings, as well as testing and inspection methods.

Once the tank has been fabricated, it undergoes several finishing processes. These include grinding and polishing, which improves the aesthetics of the tank and weld seams. It is then passivated, which removes impurities and provides a protective oxide layer. This helps to prevent corrosion and oxidation.

Stainless steel water storage tanks are used to hold water for a variety of purposes, including irrigation and agriculture, food preparation, fire-fighting, and drinking. They are available in a wide variety of sizes, and can be configured for above-ground or below-ground installation. They can also be fitted with accessories, such as dip charts and level gauges.