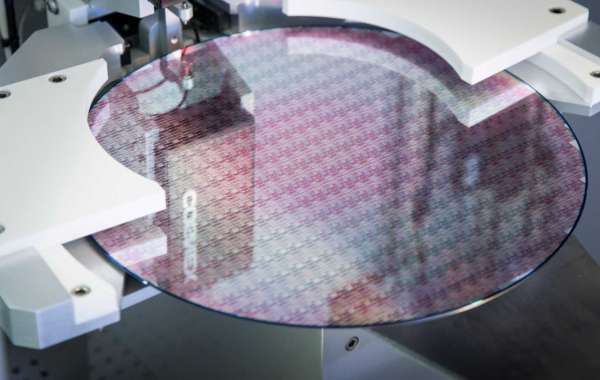

The semiconductor industry has witnessed remarkable growth and advancements in recent years. With the increasing demand for smaller, faster, and more efficient electronic devices, the need for cutting-edge semiconductor manufacturing processes has become paramount. At the heart of this revolution stands Wafer Process Systems CA, a company at the forefront of innovation in the semiconductor manufacturing equipment market.

A Brief Overview of Wafer Process Systems CA:

Wafer Process Systems CA is a California-based company specializing in the design, development, and production of advanced process systems for semiconductor manufacturing. With a team of highly skilled engineers and industry experts, the company has made significant contributions to the field, revolutionizing the way semiconductor devices are produced.

Breaking Down the Wafer Process Systems CA Advantage:

- Cutting-Edge Technology and Innovation

At the core of Wafer Process Systems CA's success lies its commitment to pushing the boundaries of technology and innovation. The company continually invests in research and development to develop state-of-the-art equipment that meets the ever-increasing demands of the semiconductor industry.

- Customization and Flexibility

Wafer Process Systems CA understands that every semiconductor manufacturer has unique requirements. To cater to these specific needs, the company offers a wide range of customizable solutions. From wafer cleaning and etching systems to deposition and thin-film coating equipment, their product portfolio is designed to address the diverse needs of the industry.

- Superior Quality and Reliability

The semiconductor manufacturing process requires precision and consistency. Wafer and Process Systems CA excels in providing equipment that delivers superior quality and reliability. Through rigorous testing and quality control measures, the company ensures that its systems meet the highest standards and can withstand the demanding environments of semiconductor fabs.

- Exceptional Customer Support

Wafer Process Systems CA takes pride in its commitment to customer satisfaction. The company provides exceptional customer support throughout the entire lifecycle of their products. From installation and training to maintenance and troubleshooting, their dedicated team of professionals is readily available to assist customers, ensuring uninterrupted operations and maximum productivity.

The Product Line of Wafer Process Systems CA:

- Wafer Cleaning and Etching Systems

Wafer Process Systems CA offers a comprehensive range of wafer cleaning and etching systems, designed to remove contaminants and impurities from semiconductor wafers. These systems employ advanced cleaning techniques, such as chemical and plasma cleaning, to achieve high levels of cleanliness required for subsequent processing steps.

The company's etching systems utilize precise etch rate control and uniformity to achieve accurate patterning on the wafer surface. Whether it's wet etching, dry etching, or plasma etching, Wafers Process and Systems CA has the expertise to deliver reliable and efficient solutions.

- Deposition Systems

Deposition is a critical step in semiconductor manufacturing, where thin films of various materials are deposited onto the wafer surface. Wafers Process Systems CA offers a range of deposition systems, including chemical vapor deposition (CVD) and physical vapor deposition (PVD) equipment.

These systems ensure precise control over film thickness, uniformity, and composition, enabling semiconductor manufacturers to achieve the desired properties and characteristics for their devices. With Wafers Process Systems CA's deposition systems, customers can have confidence in the quality and consistency of their deposited films.

- Thin-Film Coating Systems

Thin-film coatings play a crucial role in enhancing the performance and reliability of semiconductor devices. Wafer Process Systems CA provides advanced thin-film coating systems that enable the deposition of various functional coatings, such as anti-reflective coatings, dielectric films, and protective layers.

These systems employ cutting-edge techniques like sputtering and atomic layer deposition (ALD) to achieve precise film thickness control and uniformity. The result is improved device performance and increased yield, meeting the stringent requirements of the semiconductor industry.

Industry Applications and Impact:

Wafer Process Systems CA's equipment finds applications across various sectors within the semiconductor industry. From integrated circuits (ICs) and microprocessors to memory devices and sensors, their systems contribute to the production of a wide range of electronic components.

By providing reliable and high-quality process equipment, Wafer Process and Systems CA has helped semiconductor manufacturers improve production yields, reduce manufacturing costs, and enhance device performance. Their contributions have been instrumental in advancing technology and enabling the development of cutting-edge electronic devices that power our modern world.

Conclusion:

Wafer Process Systems CA has established itself as a key player in the semiconductor manufacturing equipment market through its commitment to technological innovation, customization, quality, and customer support. With a diverse product line and a strong focus on meeting the unique needs of its customers, the company continues to revolutionize the semiconductor industry.

As the demand for smaller, faster, and more advanced electronic devices continues to rise, the importance of reliable and efficient semiconductor manufacturing equipment becomes even more pronounced. Silicon Wafers and Process Systems CA is well-positioned to meet these evolving industry demands and contribute to the ongoing technological advancements that shape our future.