API 5L X42 Pipe is a widely used steel pipe specification for the transmission of oil, gas, and fluids in both onshore and offshore applications. Manufactured by Emirerri Steel, these pipes meet stringent industry standards to ensure durability, strength, and performance under extreme conditions. These pipes are commonly used in petroleum, natural gas, and water transportation systems, ensuring efficient and safe flow.

Technical Specifications

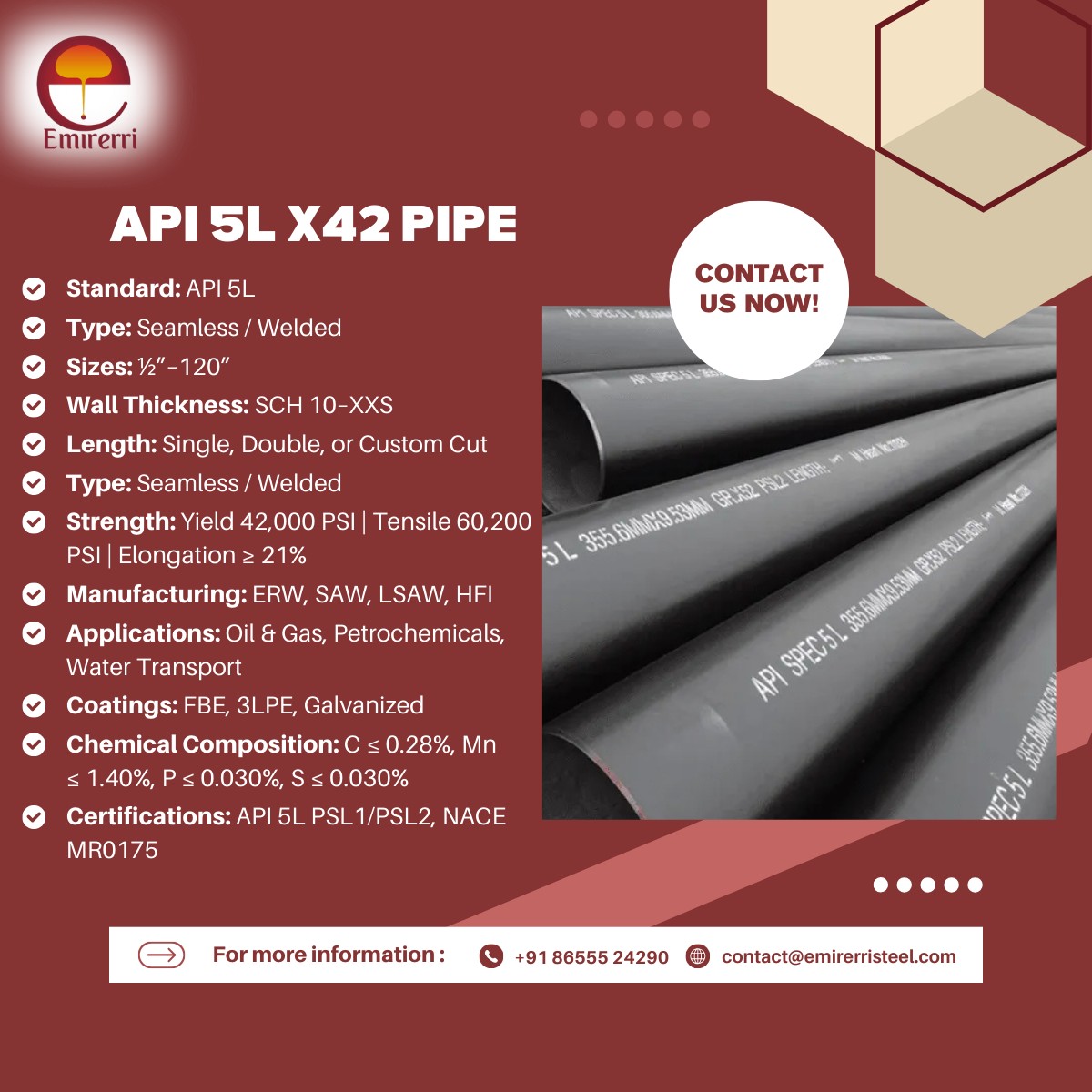

• Grade: API 5L X42

• Type: Seamless / Welded

• Standard: API 5L (ISO 3183)

• Outer Diameter: 1/2” NB to 48” NB

• Wall Thickness: SCH 10 to SCH 160, XXS

• Length: Single Random, Double Random & Cut Length

• Ends: Plain, Beveled, or Threaded

• Coating Options: 3LPE, FBE, Bare, Galvanized, Epoxy

• Pipe Form: Round, Square, Rectangular

• Manufacturing Process: Hot Rolled / Cold Drawn

• Tolerances: As per API 5L standard

Chemical Composition

API 5L X42 pipes are primarily made of carbon steel, with carefully controlled levels of manganese, phosphorus, sulfur, and other elements to enhance mechanical properties. Below is the typical chemical composition:

Element Maximum Percentage

Carbon (C) 0.28%

Manganese (Mn) 1.40%

Phosphorus (P) 0.03%

Sulfur (S) 0.03%

Silicon (Si) 0.45%

Vanadium (V) 0.06%

Molybdenum (Mo) 0.15%

Nickel (Ni) 0.50%

Mechanical Properties

• Tensile Strength: Min. 60,200 PSI

• Yield Strength: Min. 42,000 PSI

• Elongation: As per API 5L specifications

• Hardness: Controlled within API 5L standards

• Impact Strength: Retains strength under sub-zero temperatures

• Ductility: Excellent ductile performance, making it easy to form and shape

Manufacturing Process of API 5L X42 Pipe

API 5L X42 pipes are produced using advanced hot rolling and cold drawing processes to achieve precise dimensions, smooth surfaces, and superior mechanical properties. The key steps include:

1. Raw Material Selection: High-quality carbon steel billets are chosen to ensure consistency and performance.

2. Heating and Forming: The billets are heated in a furnace and shaped into seamless or welded pipes.

3. Cold Drawing (if required): For enhanced dimensional accuracy and surface finish, some pipes undergo cold drawing.

4. Heat Treatment: Pipes are subjected to normalizing, quenching, and tempering to improve strength and toughness.

5. Testing and Inspection: Each pipe undergoes rigorous quality control checks, including ultrasonic, radiographic, and hydrostatic testing.

6. Coating and Finishing: Protective coatings like 3LPE, FBE, and galvanized coatings are applied to enhance corrosion resistance.

Applications of API 5L X42 Pipe

• Oil and gas pipeline systems: Used for the safe and efficient transport of crude oil, refined petroleum, and natural gas across vast distances, ensuring the reliability of energy supply.

• Petrochemical industries: Essential for the movement of hydrocarbons, chemical compounds, and industrial fluids within chemical processing plants and refineries.

• Water transportation: Employed in municipal water supply networks, desalination plants, and irrigation systems, ensuring the safe transport of potable and non-potable water.

• Structural applications: Used in high-rise buildings, bridges, offshore platforms, and infrastructure projects for stability and support due to its high strength and durability.

• Power generation plants: Applied in thermal, nuclear, and renewable energy plants to transport steam, cooling water, and gases for efficient energy production.

• Refineries and chemical processing plants: Handles high-temperature and high-pressure fluids, making it ideal for process piping, distillation columns, and reactor systems.

• Industrial piping systems: Installed in manufacturing units, steel mills, and heavy machinery plants to transport air, steam, and other industrial gases efficiently.

• Offshore and onshore drilling operations: Used for oil extraction rigs, natural gas exploration, and subsea pipeline networks, where resistance to harsh environmental conditions is crucial.

• Storage and distribution systems for hydrocarbons: Critical for LNG and LPG transportation in storage facilities, distribution terminals, and tank farms.

• Subsea and deepwater applications: Designed to withstand extreme pressures and corrosive seawater environments, ensuring long-term performance and reliability.

• Construction industry: Commonly used in foundation piling, bridge supports, and underground piping, providing strong structural support.

• Mining and slurry pipelines: Essential in mining operations for transporting abrasive slurries, minerals, and extracted ores over long distances.

API 5L X42 Pipe Corrosion Resistance and Durability

API 5L X42 pipes are designed with superior corrosion resistance to withstand harsh environmental conditions, including exposure to saline water, chemicals, and high-pressure gases. Features include:

• 3LPE and FBE Coating: Provides a protective layer against corrosion and extends pipe life.

• Galvanized Options: Enhances resistance to oxidation and rust.

• High-Temperature Durability: Ensures structural integrity under extreme heat and pressure conditions.

• Chemical Resistance: Suitable for aggressive fluids in petrochemical industries.

API 5L X42 Pipe Welding & Fabrication

API 5L X42 pipes support multiple welding techniques, including:

• Shielded Metal Arc Welding (SMAW)

• Gas Tungsten Arc Welding (GTAW/TIG)

• Gas Metal Arc Welding (GMAW/MIG)

• Submerged Arc Welding (SAW)

Proper preheating, post-weld heat treatment, and filler selection ensure strong and defect-free weld joints, making these pipes ideal for pipeline construction, fabrication, and industrial installations.

For inquiries and orders, contact Emirerri Steel today and get the best solutions for your piping requirements.