Can Be Designed to Produce a Variety of Pallet Sizes and Configurations. Usually Used for the Transportation, Storage and Transportation of Goods.

injection pallet moulds Are Used in a Variety of Industries Including Logistics, Food and Beverage, and Manufacturing. They Offer Many Advantages, Including High Productivity, Low Labor Costs, and Excellent Dimensional Accuracy and Consistency. Plus, Plastic Pallets Are Lightweight, Durable, and Recyclable, Making Them a Popular Alternative to Traditional Wooden Pallets. injection pallet moulds Are a Popular Choice for Manufacturers Looking to Produce High Quality, Durable Pallets with Efficient Production Times and Low Cost

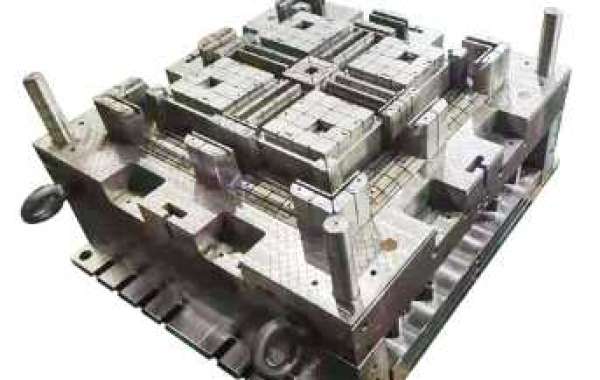

The Design of the injection pallet mould is Critical to the Quality of the Finished Product As It Determines the Shape, Size and Characteristics of the Pallet. the Design of the injection pallet mould Can Be Customized to Meet the Specific Needs of the Manufacturer. the Design Process Takes into Account Factors Such As the Size and Shape of the Pallet, the Required Load Capacity, and Any Other Specific Requirements. the Design of the injection pallet mould is Critical to the Production of High Quality Pallets. the Mold Must Be Designed to Withstand the Injection Pressure and Ensure That the Plastic Fills the Cavity Evenly.

To Ensure Consistent Quality and the Durability and Longevity of the Mold, Regular Maintenance And, if Necessary, Repair of injection pallet moulds Are Essential. This May Involve Polishing Molds, Replacing Worn Parts, and Adjusting Injection Processes. injection pallet moulds Require Regular Maintenance to Ensure They Continue to Produce High Quality Pallets. This Includes Cleaning, Lubricating, Repairing Any Damaged Parts and Inspecting the Molds for Any Signs of Wear. Proper Storage and Handling of injection pallet moulds Can Help Extend Their Life and Ensure Consistent Production Quality.

Steel injection pallet moulds Are Generally More Durable and Able to Withstand Higher Temperatures and Pressures Than Aluminum Molds. However, They Are Also More Expensive and Take Longer to Manufacture. the Production of injection pallet moulds Requires a High Degree of Precision and Accuracy. This is Because Any Defect in the Mold Will Result in a Defect in the Finished Product. the injection pallet mould is Available for Both Disposable and Reusable Pallets. Re-use to Produce Multiple Pallets Makes It a Cost-effective Option for Manufacturing Large Numbers of Pallets. Using Injection Pallet Moulds Helps Reduce Waste and Increase Sustainability in the Logistics Industry As Plastic Pallets Are Reusable and Recyclable.

Using injection pallet moulds Can Help Companies Save Money and Reduce Waste by Producing High-quality, Reusable Pallets That Last for Many Years.

In Conclusion,

Injection Pallet Mould is a Key Component in the Manufacturing Process of Plastic Pallets. They Are Precision Engineered and Manufactured to Ensure Consistently High Quality Results and Offer Numerous Benefits for Manufacturers and End Users Alike.