The Role of Advanced Fabric Bags in Erosion Control

The increasing threat of soil erosion, riverbank destabilization, and coastal degradation has led to the growing adoption of innovative solutions designed to protect and reinforce vulnerable landscapes. One such solution that has gained popularity in the construction and environmental sectors is the use of specialized Geo Bags Industries in India high-strength geotextile materials that provide an effective barrier against water-induced erosion while allowing permeability for controlled drainage. The application of these materials in hydraulic structures, flood control measures, and land reclamation projects has expanded significantly due to their cost-effectiveness and efficiency. With numerous companies involved in the development and supply of these protective solutions, the demand for high-quality products continues to rise across infrastructure and environmental protection projects.

Material Composition and Strength Factors of Fabric-Based Barriers

The efficiency of these fabric-based containment solutions is largely dependent on the type of geotextile material used in their production. Typically, they are made from either woven or non-woven polypropylene or polyester, both of which offer excellent durability and resistance to environmental stressors. The woven variations provide enhanced tensile strength, making them ideal for high-impact applications such as shoreline stabilization and embankment protection. Non-woven varieties, on the other hand, offer superior permeability, allowing for effective filtration while preventing soil displacement. The careful selection of materials and adherence to stringent quality standards ensure that these containment solutions provide long-lasting reinforcement in even the most challenging environments. Leading providers across the country are continually innovating to enhance the performance and longevity of these products.

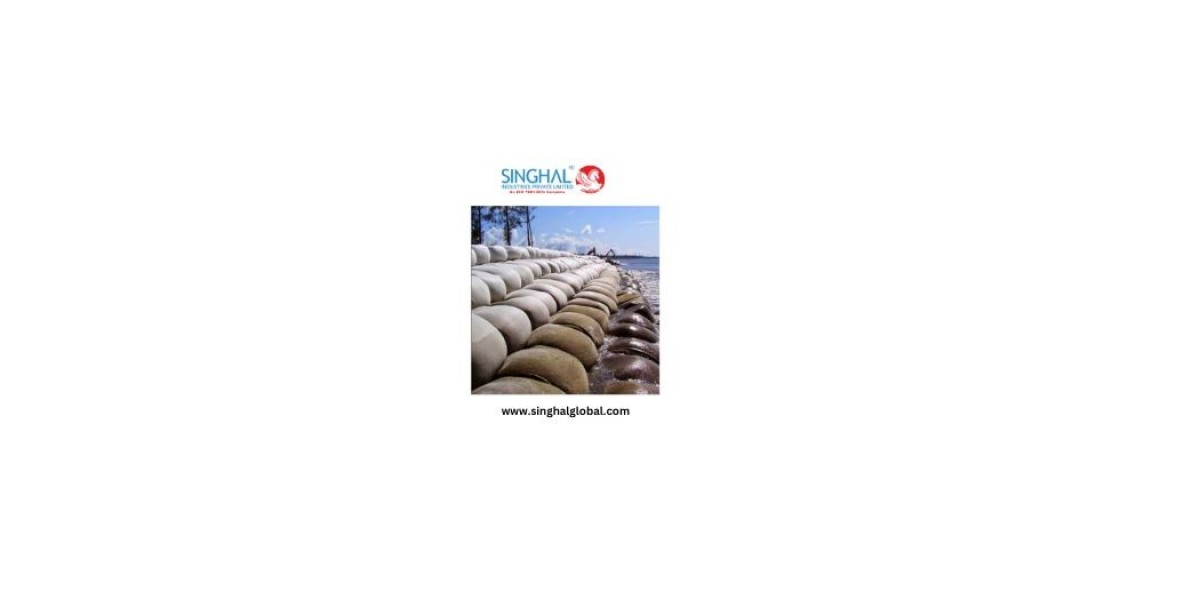

Applications in Riverbank and Coastal Protection Projects

Water-induced soil erosion is a major concern in regions with heavy rainfall, strong currents, or coastal vulnerabilities. As a result, the use of fabric-based solutions in riverbank protection and shoreline reinforcement has become a crucial aspect of environmental conservation and infrastructure development. These containment systems are filled with locally available sand or other granular materials and strategically placed along riverbanks, embankments, and shorelines to prevent soil loss. By acting as protective barriers, they help stabilize slopes, reduce sedimentation in water bodies, and mitigate the impact of wave action. Engineers and environmental planners widely incorporate these solutions into flood control projects to safeguard communities and infrastructure from the devastating effects of erosion and land degradation.

Benefits of Using Fabric-Based Solutions in Construction Projects

One of the primary advantages of using these containment solutions in construction and environmental projects is their ability to provide a flexible yet sturdy alternative to traditional hard-engineering structures. Unlike concrete and rock-based reinforcements, fabric-based containment systems offer easier installation, reducing both labor costs and project timelines. Additionally, their lightweight nature allows for easier transportation and handling, making them an efficient option for large-scale erosion control measures. The permeability of the geotextile fabric ensures that excess water is filtered while retaining essential soil components, improving overall stability and sustainability. Many construction and infrastructure companies are now integrating these solutions into their projects to enhance environmental resilience while maintaining cost-efficiency.

Sustainability and Environmental Impact of Advanced Containment Bags

As industries shift toward environmentally friendly practices, the adoption of geotextile-based erosion control measures aligns with global sustainability goals. These fabric containment systems reduce the need for extensive concrete and stone usage Geo Bag Manufacturers in India locally source fill materials; these solutions minimize carbon footprints associated with transportation and construction processes. Moreover, they offer a biodegradable or recyclable alternative in certain applications, making them an eco-conscious choice for long-term environmental management. Research and development efforts in the industry are continuously focused on enhancing the biodegradability and recycleability of these solutions to further support sustainable infrastructure development.

Customization and Engineering Innovations for Specific Project Needs

Every erosion control project has unique requirements based on soil composition, water flow intensity, and environmental conditions. To address these diverse needs, manufacturers offer customized designs and specifications, including variations in fabric weight, porosity, and UV resistance. Customizable filling options allow engineers to select appropriate materials based on site conditions and project goals. Recent innovations include reinforced stitching techniques and polymer coatings that enhance durability, ensuring that these solutions withstand harsh weather conditions and prolonged exposure to water. As technology advances, the efficiency of these protective barriers continues to improve, allowing engineers to implement more effective erosion control strategies.

Industry Growth and Expanding Markets for Protective Fabric Bags

The rising awareness of erosion-related issues and the need for effective soil stabilization solutions have contributed to the rapid expansion of the market for these advanced containment products. Infrastructure development projects, environmental restoration initiatives, and flood mitigation efforts continue to drive demand. Governments, private organizations, and environmental agencies are increasingly investing in these solutions to combat the adverse effects of climate change and land degradation. As a result, manufacturers across various regions are scaling up production capacities and adopting advanced manufacturing techniques to meet the growing demand. The expanding application of these materials in new industries further reinforces their significance in modern engineering and environmental management.

Conclusion: The Future of Fabric-Based Erosion Control Systems

The continuous advancement of erosion control techniques has positioned geotextile-based containment solutions as a preferred method for protecting landscapes and infrastructure. Their adaptability, affordability, and sustainability make them an ideal choice for a wide range of applications, from riverbank reinforcement to construction site stabilization. With ongoing research and technological developments, the efficiency and durability of these solutions will increase. As Geo Bag Exporters in Ahmedabad continue to seek eco-friendly and effective methods for land preservation, the demand for high-quality protective fabric bags will remain strong. The role of innovation and engineering excellence in this sector will be crucial in ensuring that future projects achieve both environmental and economic sustainability.

Frequently Asked Questions (FAQs)

How do these fabric-based containment solutions compare to traditional erosion control methods?

Unlike concrete or stone-based reinforcements, fabric-based solutions offer flexibility, cost-effectiveness, and ease of installation. They provide natural drainage while preventing soil loss, making them a practical choice for erosion control projects.

What factors should be considered when choosing the right product for a project?

The selection of the appropriate solution depends on project-specific factors such as soil type, water flow conditions, load-bearing requirements, and environmental exposure. Consulting with industry experts ensures that the right specifications are chosen for maximum effectiveness.

Can these solutions be used for temporary and permanent applications?

Yes, they are suitable for both short-term and long-term applications. While some variations are designed for temporary flood mitigation, others are engineered for permanent soil stabilization and landscape protection.

Are these containment systems environmentally sustainable?

Yes, they contribute to sustainability by reducing reliance on heavy construction materials, minimizing ecological disturbances, and offering recyclable or biodegradable options in certain applications. Their use aligns with global efforts to promote eco-friendly engineering practices.