The automotive industry is built on high-precision engineering, requiring components with tight tolerances to ensure optimal performance, safety, and efficiency. As the demand for advanced vehicle technology grows, high-accuracy machining solutions play a critical role in manufacturing essential automotive components. This article explores how custom machining services are revolutionizing the automotive sector and why Premium Parts Manufacturing Limited remains a trusted name in delivering precision machining services.

What Is Precision Machining in Automotive Manufacturing?

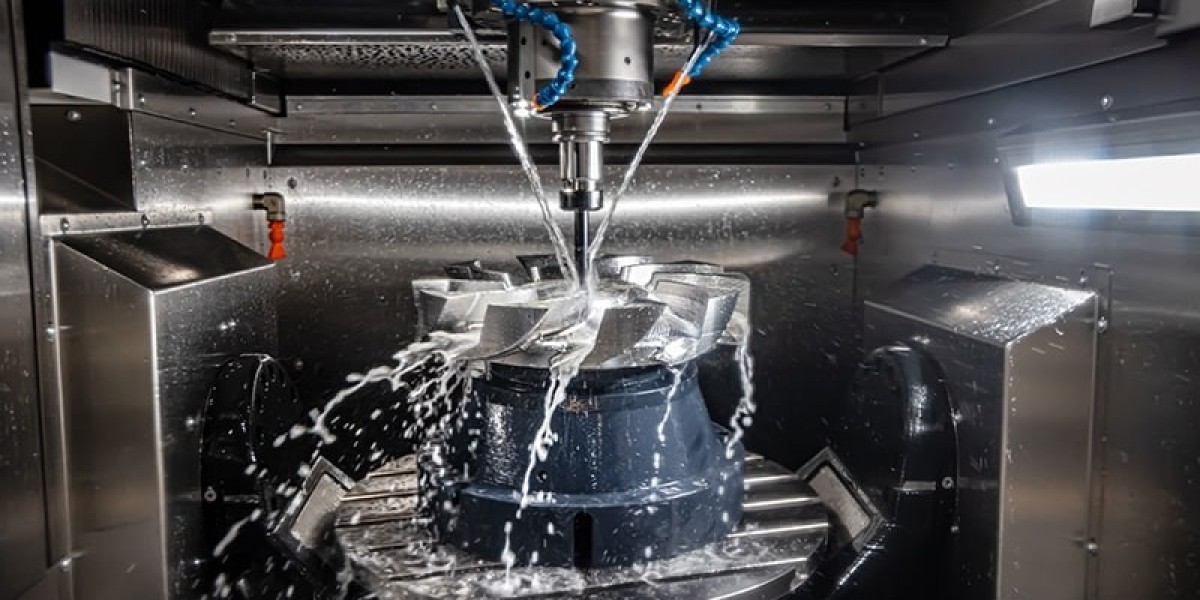

Precision machining, also known as close-tolerance machining, involves the use of computer-controlled tools to shape, cut, and refine automotive parts with extreme accuracy. This process ensures that metal, plastic, and composite components fit seamlessly into larger automotive assemblies.

Common Precision Machined Automotive Parts

Engine Components: Pistons, cylinders, crankshafts, and camshafts

Transmission Parts: Gears, shafts, and clutch components

Brake System Parts: Discs, calipers, and hydraulic components

Suspension & Steering Components: Ball joints, tie rods, and control arms

Electrical System Components: Connectors, housings, and sensor mounts

Key Advantages of Custom Machining Solutions in Automotive

1. Superior Accuracy & Consistency

Advanced CNC machining services ensure that each automotive component meets exact specifications with minimal deviation, improving performance and reducing errors in mass production.

2. Cost-Effective Production

High-volume manufacturing benefits from automated machining processes, reducing labor costs and material waste while maintaining high precision in component production.

3. Enhanced Durability & Performance

Automotive parts made using precision cutting techniques are more durable, leading to improved vehicle reliability and longevity.

4. Support for Innovation & Customization

With the rise of electric and hybrid vehicles, high-accuracy manufacturing allows for the development of complex components tailored to new automotive technologies.

5. Rapid Prototyping & Shorter Production Cycles

Through rapid machining services, manufacturers can quickly develop and test new designs before moving to full-scale production, reducing lead times and accelerating product innovation.

Precision Engineering Techniques Used in Automotive Manufacturing

1. CNC Milling & CNC Turning

CNC milling provides multi-axis precision cutting for intricate automotive parts.

CNC turning ensures smooth, cylindrical components like shafts and gears.

2. Electrical Discharge Machining (EDM)

Used for complex shapes and hard metals, EDM enhances automotive part precision where traditional methods may fail.

3. Grinding & Honing

These processes ensure fine surface finishes and exact tolerances for components requiring high friction resistance.

4. Laser Cutting & Welding

Laser technology is used to achieve micro-precision fabrication, critical for automotive electrical systems and intricate components.

Premium Parts Manufacturing Limited: Your Trusted Partner in Precision Machining

At Premium Parts Manufacturing Limited, we specialize in custom machining services for the automotive sector. Our state-of-the-art CNC machining solutions ensure the highest standards of accuracy, efficiency, and quality.

Why Choose Us?

✅ Advanced Machining Technology for precise automotive part production

✅ High-Quality Materials including aluminum, steel, titanium, and composites

✅ Strict Quality Control Measures ensuring consistent, reliable output

✅ Rapid Prototyping & Mass Production Capabilities

✅ Cost-Effective Solutions for both small and large-scale manufacturing needs

Future of Precision Machining in the Automotive Industry

The integration of Industry 4.0 technologies, including AI-driven machining, automation, and real-time data analytics, will further enhance precision engineering in automotive manufacturing. Premium Parts Manufacturing Limited remains at the forefront of these innovations, providing highly accurate machining solutions tailored to the evolving demands of the automotive sector.

Conclusion

From engine components to safety-critical systems, custom machining solutions continue to play an integral role in shaping the automotive industry. As vehicles become more advanced, lightweight, and efficient, the need for close-tolerance manufacturing will only increase. With expertise in CNC precision machining, Premium Parts Manufacturing Limited is committed to delivering high-accuracy automotive parts that meet and exceed industry standards.

FAQs About Precision Machining in Automotive Manufacturing

1. What is the importance of precision machining in automotive manufacturing?

Precision machining ensures that automotive components meet exact specifications, improving vehicle performance, safety, and reliability.

2. Which automotive parts require precision machining?

Engine components, transmission parts, brake systems, suspension parts, and electrical housings all rely on high-accuracy manufacturing.

3. How does CNC machining improve automotive part quality?

CNC machining enhances accuracy, repeatability, and efficiency, ensuring consistent production of tight-tolerance components.

4. What materials are used in precision machining for automotive applications?

Common materials include aluminum, stainless steel, titanium, brass, and engineered plastics.

5. How does precision machining support electric vehicle (EV) production?

Precision machining enables the development of lightweight, high-performance components crucial for EV batteries, powertrains, and electronic systems.

For more details on how Premium Parts Manufacturing Limited can help your business with custom machining solutions, contact us today!