Ferro titanium cored wire and lumps are essential materials in modern metal processing industries. As key offerings from ferro alloys suppliers in India, these additives play a crucial role in refining steel and alloys by enhancing mechanical properties, improving deoxidation, and reducing impurities. As industries strive for superior quality and efficiency, Ferro Titanium products have become indispensable in metallurgy. This article explores the industrial benefits of metal processing and their impact on manufacturing and production quality.

Role of Ferro Titanium Cored Wire in Metal Processing

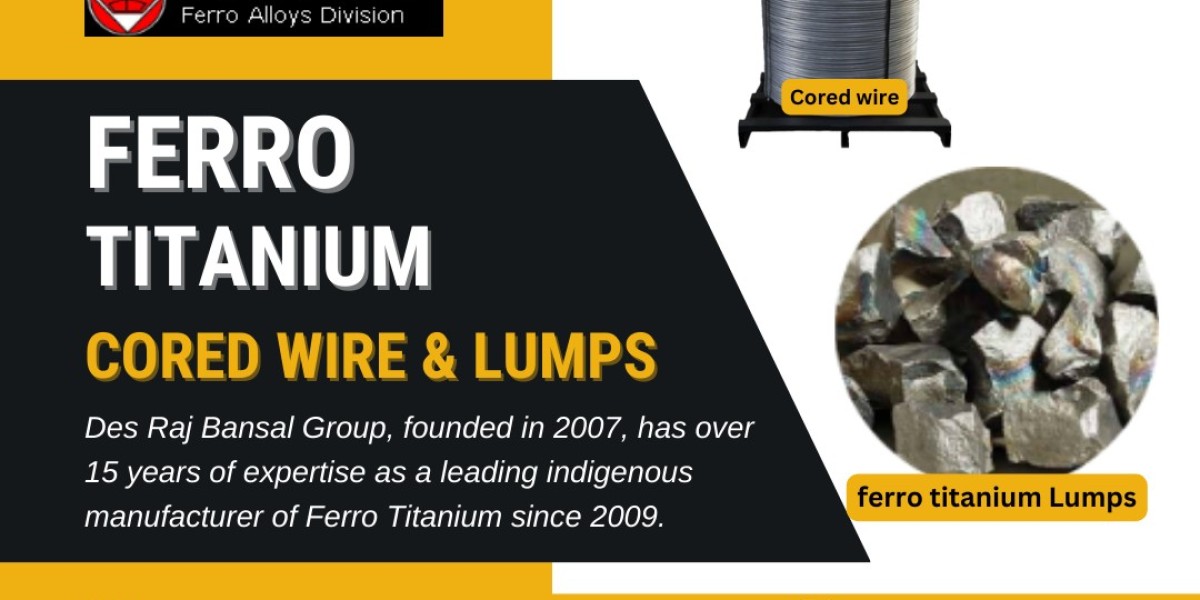

Ferro Titanium Cored Wire is widely used in steelmaking and foundries to refine and improve the properties of molten metal. The wire is composed of finely controlled Ferro Titanium powder encapsulated in a steel sheath, allowing for precise additions to the molten bath.

Key Benefits:

Deoxidation & Desulfurization: Ferro Titanium Cored Wire effectively removes oxygen and sulfur, reducing unwanted inclusions in steel.

Grain Refinement: It promotes fine grain structure, improving strength, toughness, and ductility in the final product.

Carbide Formation: The addition of Titanium forms stable carbides and nitrides, enhancing wear resistance and hardness.

Precise Alloying: Controlled feeding of cored wire ensures consistent composition, minimizing wastage and improving process efficiency.

Reduction of Slag Formation: The wire enhances steel cleanliness by minimizing non-metallic inclusions, leading to high-quality end products.

Applications of Ferro Titanium Lumps in Metallurgy

Ferro Titanium Lumps are widely used in steelmaking, welding electrode manufacturing, and alloy production. Their role extends beyond alloying, influencing the overall quality and durability of metal components.

Key Industrial Benefits:

Titanium Enrichment: Ferro Titanium Lumps are a rich source of Titanium, contributing to the formation of strong, lightweight, and corrosion-resistant alloys.

Welding Industry Applications: These lumps are used in welding electrodes to enhance arc stability and reduce porosity.

Improved Casting Performance: Ferro Titanium helps prevent gas porosity and shrinkage, ensuring smooth and defect-free castings.

Resistance to High Temperatures: The presence of Titanium improves heat resistance, making the material suitable for high-performance applications.

Cost-Effective Additive: Compared to pure Titanium, Ferro Titanium Lumps offer a cost-effective solution for improving metal properties.

Impact on Steel and Alloy Manufacturing

Both Ferro Titanium Cored Wire and Lumps contribute significantly to the steel and alloy industry, optimizing the refining process and enhancing final product quality. These materials are particularly beneficial in producing high-strength low-alloy (HSLA) steel, stainless steel, and superalloys used in aerospace, automotive, and heavy machinery sectors.

Advantages in Steelmaking:

Enhanced Mechanical Properties: Increases toughness, wear resistance, and impact strength.

Improved Corrosion Resistance: Makes alloys suitable for marine, aerospace, and chemical processing applications.

Environmental Benefits: Reduces the need for excessive raw material consumption and minimizes metal waste.

Conclusion

Ferro titanium cored wire and lumps have become indispensable in modern metal processing, offering numerous industrial benefits. From improving deoxidation and grain refinement to enhancing corrosion resistance and mechanical strength, these materials play a critical role in steelmaking and alloy production. As industries continue to evolve, the demand for high-performance Ferro Titanium products will only grow, reinforcing their importance in metallurgical advancements.

By incorporating Ferro Titanium into metal processing, manufacturers can achieve superior quality, improved efficiency, and long-term cost savings, making it a valuable investment for the future of metallurgy.

#FerroTitaniumCoredWire #FerroTitaniumLumps #FerroAlloysSuppliers #FerroTitanium