Understanding Electronic Skin Industry Technology

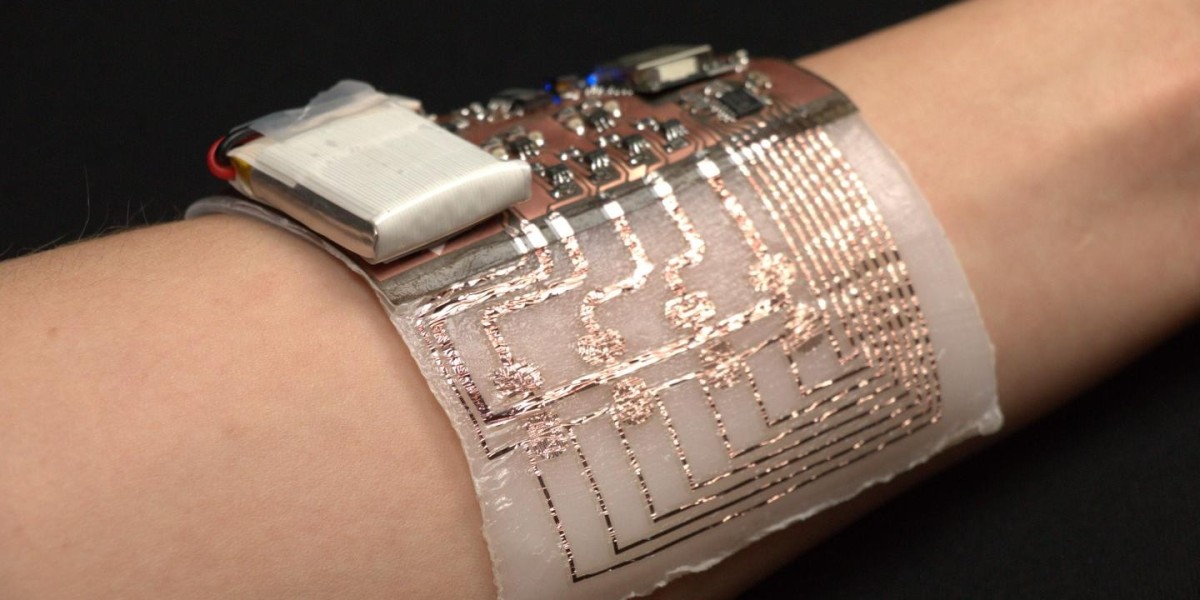

Electronic skin, also known as e-skin or artificial skin, is a material designed to replicate the functions of human skin. It is made up of several layers that work together to provide humans and robots with a sense of touch. The top layer is usually made from a flexible, thin material that mimics the outer layer of real skin called the epidermis. Underneath is a sensor layer packed withtiny electronic sensors and circuits that can detect touch, heat, pressure and other stimuli. The sensor signals are transmitted through a third layer to an electronics platform that interprets the data and determines how to respond. The goal of e-skin is to provide the ability to detect subtle environmental changes and physical interactions, much like humans can with their own skin.

Major Players Leading Development

Several major technology companies and research institutions around the world are working to advance e-skin technologies. Samsung, for example, has developed a stretchable electronic skin capable of detecting different gestures when placed on the wrist. The e-skin contains embedded circuits made from elastic polymers and micro-LEDs to detect movement. Researchers at the University of Tokyo have also demonstrated highly flexible and durable electronic skin able to self-heal when torn. The e-skin incorporates liquid metal circuits that can autonomously repair if physically damaged. In the United States, researchers at the University of Colorado Boulder have created an electronic skin capable of recreating the sense of touch with 17 pressure sensors per square inch of synthetic skin.

Applications in Prosthetics and Robotics

One of the most promising applications of Electronic Skin is in prosthetic devices and robotics. For those with limb amputations, e-skin prosthetics could help provide more lifelike and functional replacement limbs with integrated touch capabilities. With e-skin, prosthetics may be able to better sense pressure, heat and textures to improve control and safety. Researchers at the Max Planck Institute in Germany are developing e-skin capable of differentiating between 16 tactile tasks to one day help prosthetic hand users grasp and manipulate objects. In robotics, e-skin allows machines to physically interact with humans safely by detecting potential harms from excessive pressure or heat. Soft robotics companies like Anthropic are applying e-skin to help robots perform tasks like handling fragile objects without breaking them. As the technology advances, e-skin will continue enhancing man-machine interaction through artificial touch.

Mass Production Challenges

While promising advances are being made in e-skin R&D labs, mass producing the technology at scale presents various technological and manufacturing challenges that must still be addressed. Current methods for assembling e-skin sensors and circuits are often complex, time-consuming and not well-suited for high-volume production. The materials used like liquid metals and polymers can also degrade more quickly than conventional electronics. This makes developing a robust, low-cost manufacturing process that can stand up to everyday wear and tear a difficult task. Spin-off companies from research institutions like MC10 in the US are making strides in scaling up printing techniques for flexible bioelectronics but larger-scale e-skin is still years away. Resolving these mass production challenges will be key to unlocking the true commercial potential of electronic skin technologies across industries.

Growing Global Market Opportunity

Despite production hurdles, research firms project the global electronic skin market will witness explosive growth in the coming decades as the technology matures. According to a recent report from MarketsandMarkets, the e-skin market size is expected to rise from $56 million in 2022 to over $4 billion by 2030, growing at an impressive CAGR of over 31% during this period. North America and Europe currently dominate R&D spending and market revenues due to high research intensity in these regions.

Asia Pacific is anticipated to become the largest market by the late 2020s as major players like Samsung, Riiken and others ramp up production. As electronic skin industry infiltrates new verticals across healthcare, consumer goods and industrial sectors, nations that play a leading role in commercializing the technology stand to gain significant economic opportunities and competitive advantages globally. This includes establishing manufacturing capabilities as well as innovating advanced applications and integration into products. Therefore, the race is on for governments, startups and corporations worldwide to solidify their footprint in the promising new market of electronic skin.

Get More Insights on Electronic Skin

Choose your preferred language for better understanding-

About Author-

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.

(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)