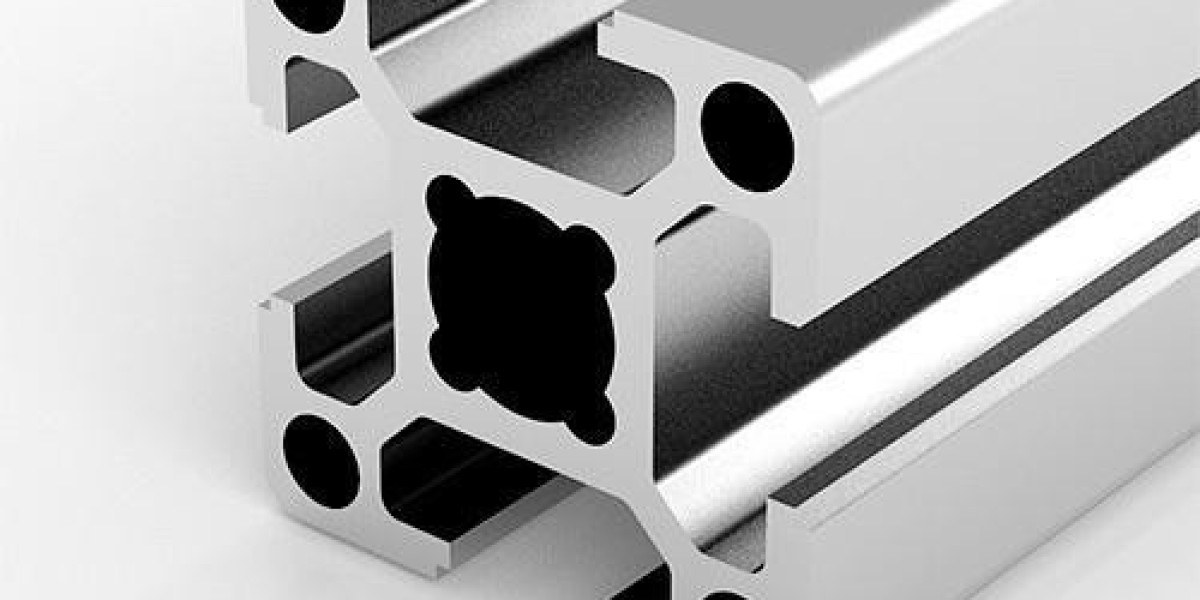

Aluminum extrusion is a manufacturing process used to create objects of a fixed cross-sectional profile. It uses aluminum alloyed with various elements like magnesium, copper, zinc, and others. During extrusion, this material is pushed through a die opening to give it the desired shape. This allows forming very long and consistent aluminum profiles.

Materials Used in Aluminum Extrusion

The main material used is aluminum or aluminum alloys. Pure aluminum has properties like light weight, non-toxic, corrosion resistance, and more. However, it has low strength and formability. As such, it is almost always alloyed with other metals like:

- Magnesium: Provides high strength to aluminum and improves formability. The 6000 series has 1-2.5% Mg.

- Copper: Improves strength and electrical conductivity. Commercial purity alloys have ≤0.25% Cu. Durable alloys like 2000, 7000 series have 3-5% Cu.

- Zinc: Improves strength but decreases ductility. The 7000 series contains 5-6% Zn.

- Manganese: Used in small amounts in aluminum alloys to improve workability.

- Silicon: Improves fluidity during casting. The 400 series contains 7-13% Si.

Extrusion Process

The main stages in aluminum extrusion are:

1. Pre-heating: Aluminium Extrusion billets or logs are pre-heated using natural gas or electricity in a chamber at around 480-520°C. This softens the material.

2. Load press: The heated billet is loaded into the container or pot of the extrusion press.

3. Forging: A hydraulic or mechanical ram forces the billet through a steel die opening, which is engraved with the desired cross-section profile.

4. Drawn out: The extruded material is continually drawn out of the die as the ram forces it. Lengths up to 300 m are possible.

5. Cut-off: The extruded profile is cut into desired lengths by saws or shear blades.

6. Heat treatment: If needed, the extrusions may undergo heat treatment like quenching, natural aging, etc. to achieve the final mechanical properties.

7. Finishing: The finished extrusions may undergo sandblasting, anodizing, etc. for corrosion protection or appearance enhancement.

Dies and Tooling

Extrusion dies are precision machined to tight tolerances and come in various configurations based on required shape. They range from simple to complex multi-cavity designs. Other tooling includes pot hardware, billet holder, breakout tooling, indexing mechanisms and more. Diamond tooling is used for machining, with tungsten carbide for die inserts.

Applications

Due to its versatility and high strength-to-weight ratio, they find use in:

- Construction: Windows, doors, curtain walls, structural beams.

- Transportation: Automotive components, truck/bicycle frames, railway carriages, aircraft parts.

- Electrical: Heat sinks, housings, transmission towers, cables.

- Consumer Durables: Furniture, ladders, playground equipment.

- Industrial: Equipment enclosures, hydraulic cylinders, heat exchangers.

Advantages of Aluminum Extrusion

- Dimensional accuracy and consistency of profiles

- Ease of forming complex cross-sections in single operation

- Uniform mechanical properties along length

- Material utilization >90%, lesser waste

- Self-lubricating nature for sliding contacts

- Aesthetic appeal and finish options

- High strength-to-weight ratio

- Corrosion resistance with proper treatment

- Energy efficiency - uses 5% of energy used for steel

This covers the major aspects involved in the aluminum extrusion manufacturing process. With its versatile forming ability and material advantages, aluminum extrusions continue growing in demand across diverse industries. New alloy developments also widen its application scope further.

Explore More About Aluminium Extrusion

Choose your Preferred language for better understanding-

About Author-

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. With an MBA in E-commerce, she has an expertise in SEO-optimized content that resonates with industry professionals. (https://www.linkedin.com/in/ravina-pandya-1a3984191)