High-density polyethylene (HDPE) duct spacers play a crucial role in the installation and support of underground conduit systems. These spacers ensure that ducts remain properly aligned and spaced during installation, providing structural integrity, protection, and efficient cable management in various infrastructure projects. HDPE duct spacers are commonly used in telecommunications, electrical, and gas pipeline projects, helping to protect cables from external damage and ensure smooth installation. In this article, we will explore the factors affecting the HDPE duct spacer price, the process of choosing a reliable HDPE duct spacer supplier, and guidelines for proper HDPE duct spacer installation.

Understanding HDPE Duct Spacers

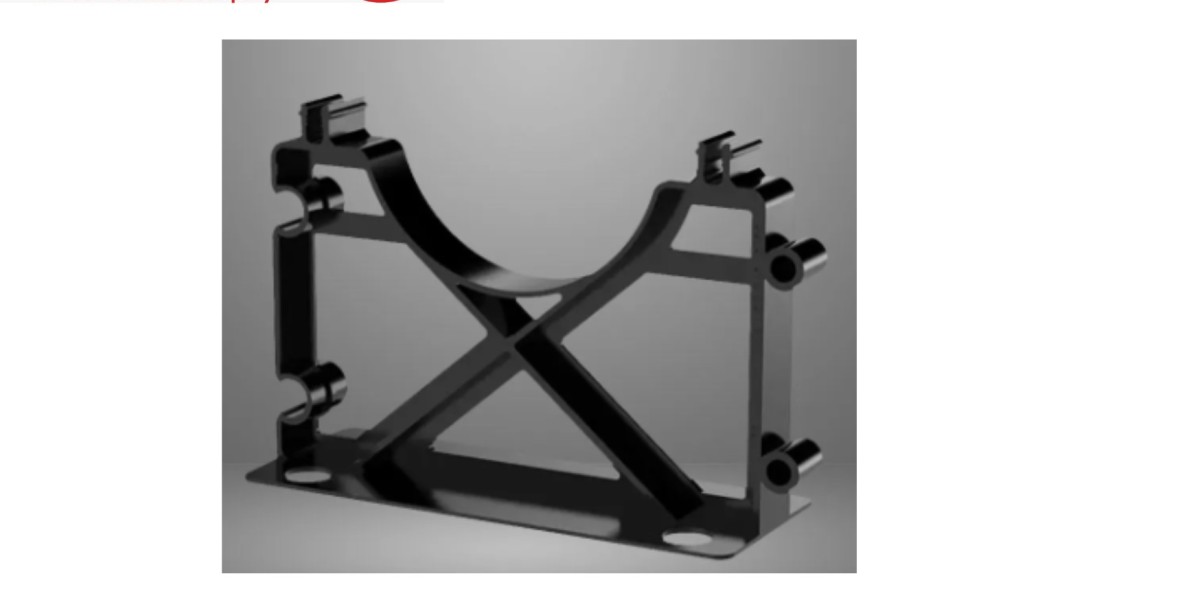

An HDPE duct spacer is a specially designed component used to maintain uniform spacing between multiple ducts or conduits during underground or above-ground installations. These spacers help prevent ducts from shifting or collapsing, allowing for smooth cable installation and reducing the risk of damage over time. HDPE duct spacers are preferred because they offer exceptional durability, flexibility, and resistance to environmental factors like moisture, temperature fluctuations, and chemical exposure.

Factors Affecting HDPE Duct Spacer Price

The HDPE duct spacer price can vary depending on several factors. Understanding these factors can help project managers and contractors make informed decisions while sourcing the appropriate duct spacers for their needs. The main factors influencing price include:

Spacer Size and Configuration: HDPE duct spacers are available in different sizes and configurations, depending on the number of ducts and their diameters. Larger or custom-sized spacers designed to accommodate more ducts will typically cost more than standard versions.

Material Quality: The grade of HDPE used in manufacturing the spacer also impacts its price. High-quality HDPE offers greater resistance to environmental stress, UV rays, and chemicals, which ensures longer-lasting performance but may come at a higher cost. Investing in premium-grade spacers can lead to fewer replacements and better durability over time.

Spacer Design and Features: Some HDPE duct spacers come with advanced features, such as snap-locking mechanisms or adjustable arms for easier installation and flexibility. These enhanced design elements can increase the price but improve ease of use and adaptability to various projects.

Quantity Ordered: Like many industrial products, the HDPE duct spacer price is influenced by the order volume. Larger projects that require bulk purchases often receive discounts, making it more economical to buy in large quantities.

Customization: Custom HDPE duct spacers designed to meet specific project requirements can affect the price. Special dimensions, configurations, or added features like reinforced strength for high-load applications may increase the overall cost.

Supplier Location and Shipping Costs: The geographic location of the supplier can also influence the price. While local suppliers may offer lower shipping costs, imported spacers or those sourced from international suppliers may involve additional fees. The cost of transportation, especially for bulk orders, can significantly affect the overall expense.

Considering these factors will help you assess the cost and choose the best HDPE duct spacers for your specific project while ensuring cost-efficiency and reliability.

Choosing the Right HDPE Duct Spacer Supplier

Selecting a reliable HDPE duct spacer supplier is essential to ensure that your project remains on schedule and meets the required safety and performance standards. When evaluating potential suppliers, it is important to consider the following factors:

Product Range and Customization: A reputable supplier should offer a wide variety of duct spacer sizes, configurations, and designs to accommodate different project needs. Additionally, if your project requires custom HDPE duct spacers, ensure the supplier has the capability to produce them to your specifications.

Quality Assurance and Certifications: Look for suppliers who adhere to recognized quality standards, such as ISO certification or other industry-specific certifications. This guarantees that the products have undergone rigorous testing and meet the necessary safety and performance standards.

Experience and Reputation: A supplier with extensive experience in the industry is more likely to provide reliable, high-quality products. Check for customer reviews, case studies, or testimonials that demonstrate the supplier’s track record in delivering quality products on time.

Customer Support: Reliable HDPE duct spacer suppliers offer excellent customer support, including technical assistance, product recommendations, and after-sales service. They should also be responsive to inquiries about pricing, bulk orders, and delivery timelines.

Competitive Pricing: While price is an important consideration, it’s crucial not to compromise on quality. Ensure that the supplier offers competitive pricing for high-quality spacers that meet your project’s requirements. Also, ask about potential discounts for bulk purchases.

Sustainability and Innovation: With growing environmental concerns, many industries are moving towards sustainable products. Check if the supplier adopts eco-friendly manufacturing practices or offers recyclable HDPE spacers, aligning with the industry’s push toward green solutions.

By taking the time to vet potential suppliers, you can ensure that you receive high-quality products, timely deliveries, and good value for your investment.

HDPE Duct Spacer Installation: Best Practices

Proper HDPE duct spacer installation is crucial for maintaining the structural integrity and performance of underground duct systems. Following best practices ensures that the ducts remain properly aligned and that the spacers perform their intended function over the long term.

Site Preparation: Before beginning the installation process, ensure that the site is clear of debris and properly marked. Accurate measurements should be taken to determine the correct placement of the duct spacers, ensuring that the conduits are evenly spaced.

Spacer Placement: The duct spacers should be placed at regular intervals, typically every 5 to 10 feet, depending on the project requirements and the type of load or pressure the ducts will experience. Ensuring consistent placement of the spacers helps prevent duct sagging or misalignment over time.

Alignment and Leveling: During installation, make sure that all ducts are properly aligned and level before securing the HDPE duct spacers. Misaligned ducts can result in uneven loads and possible damage to cables or pipes. Proper alignment will also make it easier to install cables or wires inside the ducts later on.

Secure Connections: If the duct spacers come with locking or snap-fit mechanisms, ensure that each connection is secure and properly locked. This will prevent the ducts from moving or shifting during installation or under environmental stresses such as ground movement or temperature fluctuations.

Pressure Testing (if applicable): After installation, especially in gas or fluid pipeline applications, it’s crucial to conduct pressure tests to ensure the system’s integrity. While HDPE duct spacers themselves don’t hold pressure, they help maintain the integrity of the ducts, preventing leaks and structural weaknesses.

Regular Maintenance: Once installed, regular maintenance is important to ensure the long-term performance of the HDPE duct system. Periodic inspections can identify any issues, such as spacer wear or duct misalignment, allowing for timely repairs or replacements before more significant problems arise.

Proper installation ensures that the HDPE duct spacers maintain their structural integrity, provide adequate support to the ducts, and allow for the smooth passage of cables or fluids. Following these guidelines will help extend the lifespan of the duct system and reduce the need for future maintenance.

Conclusion

HDPE duct spacers play a vital role in supporting and protecting underground and above-ground duct systems in a wide range of infrastructure projects. By understanding the factors that affect HDPE duct spacer price, selecting a reliable HDPE duct spacer supplier, and following best practices for HDPE duct spacer installation, you can ensure the success and longevity of your duct system. High-quality duct spacers provide the necessary support to keep ducts aligned and protected, helping to prevent cable damage and ensuring long-term system reliability. Whether you're involved in telecommunications, electrical systems, or gas pipelines, investing in quality HDPE duct spacers is essential for a durable and effective duct installation.

Here Are Three Related For HDPE duct spacer supplier

Q1: What factors influence the HDPE duct spacer price?

Ans: The price depends on spacer size, material quality, design features, order volume, customization, and supplier location.

Q2: How do I choose the right HDPE duct spacer supplier?

Ans: Look for suppliers with a wide product range, quality certifications, good customer support, competitive pricing, and a proven industry reputation.

Q3: What are the key steps in HDPE duct spacer installation?

Ans: Ensure proper site preparation, consistent spacer placement, accurate alignment, secure connections, and regular maintenance for long-lasting performance.