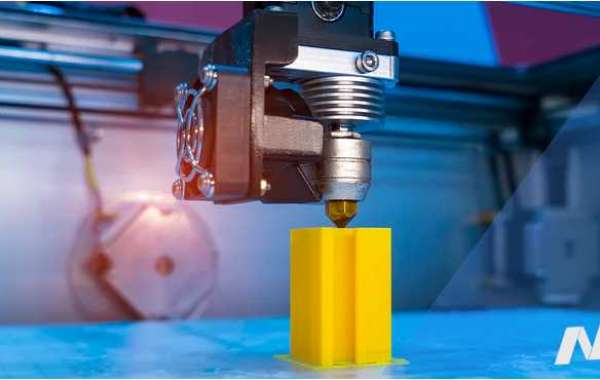

While plastic 3D printing has been widely used for rapid prototyping and low-cost production, metal 3D printing offers a range of benefits that make it an attractive option for certain industries.

One significant advantage of metal 3D printing is its strength and durability. Metal parts can withstand high temperatures and pressures, making them ideal for use in the aerospace, automotive, and medical industries. For example, metal parts can be used to create lightweight yet strong components for aircraft engines or surgical implants.

Another benefit of metal 3D printing is its ability to produce complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods. This opens up new design possibilities and allows for the creation of custom-made parts tailored to specific needs.

Strength and durability of metal 3D printing

Ability to withstand high temperatures and pressures

Ideal for aerospace, automotive, and medical industries

Production of lightweight yet strong components

Creation of complex geometries

New design possibilities

Custom-made parts tailored to specific needs

Industries that could benefit most from metal 3D printing include aerospace, automotive, medical, and defense. In these industries, precision and durability are essential, and the ability to create customized parts can lead to increased efficiency and cost savings.

Norck's new Metal 3D Printing technology offers these advantages along with the precision and efficiency enhancements provided by CNC machining. By adopting this technology, industries can take advantage of the benefits offered by metal 3D printing while also benefiting from Norck's expertise in precision manufacturing.