The Iron Oxide market is estimated to be valued at US$ 2.52 Bn in 2023 and is expected to exhibit a CAGR of 5.2% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

Iron oxide refers to rust which occurs due to oxidation of iron. It has wide applications in construction industry for its color pigment properties. It is used in cement, mortar and other construction materials to provide aesthetic appearance. It is also used in paints, coatings, plastics and ceramics industries as color pigment. The product comes in various shades of red, yellow, brown and black based on its chemical composition.

Market Dynamics:

The growth of the iron oxide market is majorly driven by rising expenditure on construction activities globally. According to OECD, the global construction industry is estimated to grow by 85% with annual spending expected to reach over $15.5 trillion by 2030. The rapidly growing urbanization and infrastructure development projects are increasing the consumption of construction materials such as cement, mortar and paints wherein iron oxide find extensive applications.

Additionally, increasing consumption of plastics globally is also fueling the demand for color pigments including iron oxide. Plastics industry accounts for over 30% share in total color pigments consumption due to wide usage of plastics in packaging, automobile and consumer goods. The global plastic production is estimated to double by 2050. This rising plastic production will subsequently drive the demand for color pigments over the forecast period.

SWOT Analysis

Strength: Iron oxide has strong resistance to heat, chemicals and weathering making it suitable for high-performance applications. It can impart different colors like red, yellow, brown and black depending on the oxidation state. Production of iron oxide pigments is a well-established process with optimized production techniques.

Weakness: High prices of micronized and nano iron oxides limits their use in some cost-sensitive applications. Dependence on availability of raw materials like iron ore leads to supply chain vulnerabilities.

Opportunity: Growing paints and coatings industry driven by rising construction activities especially in Asia Pacific and Middle East provides growth opportunities. Increasing demand from personal care products due to rising focus on natural and organic ingredients acts as an opportunity.

Threats: Volatile iron ore prices and currency fluctuations impact production costs. Strong competition from substitutes like toxic cadmium-based pigments poses threats.

Key Takeaways:

The global iron oxide market is expected to witness high growth, exhibiting CAGR of 5.2% over the forecast period, due to increasing paints and coatings consumption. Growing construction activities especially in India, China and other Southeast Asian countries will drive the demand for paints and coatings containing iron oxide pigments.

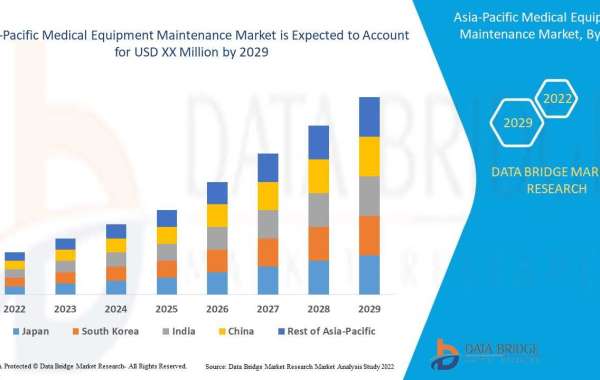

Regional analysis Asia Pacific dominates the global iron oxide market, accounting for around 45% of the overall demand in 2023. China contributes significantly to the regional market owing to presence of a booming construction industry as well as manufacturing hubs for paints, plastics and construction chemicals. India is anticipated to exhibit fastest growth during the forecast period due to ongoing infrastructure development projects under various government schemes.

Key players operating in the iron oxide market are LANXESS AG, Huntsman International LLC, Cathay Industries, Toda Kogyo Corporation, Alabama Pigments Company, LLC, Jiangsu Yuxing Industry And Trade Co., Ltd., Gotcha Pigments, Shenghua Group Deqing Huayuan, Pigment Co., Ltd, Hunan Three-Ring Pigments Co., Ltd., Yaroslavsky Pigment Company And Tata Pigments Company. Key players focus on enhancing production capacity utilizing advanced technologies to cater to the growing demand from different end-use industries.