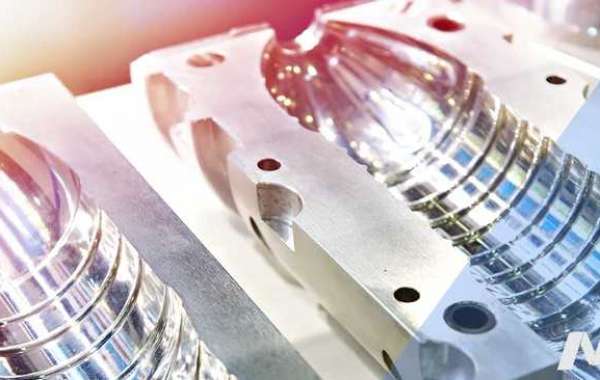

Plastic Injection Molding is a cutting-edge manufacturing process revolutionizing the production of intricate plastic components. This method, widely employed in various industries, involves injecting molten plastic material into a meticulously crafted mold, creating precise and complex shapes with exceptional accuracy. The process begins with the careful selection of thermoplastic polymers, ensuring optimal material properties for the intended application. As the molten plastic is injected under high pressure into the mold, it takes on the mold's shape, resulting in a seamless and uniform final product.

This versatile technique is renowned for its efficiency, scalability, and cost-effectiveness in mass production, making it a go-to solution for the creation of diverse items, from automotive parts to consumer goods. Plastic Injection Molding boasts rapid production cycles and low wastage, contributing to sustainable manufacturing practices. With its ability to produce intricate designs and accommodate a wide range of materials, this method stands as a cornerstone in modern manufacturing, meeting the demands of precision and customization in today's dynamic market.