Make sure that regular maintenance and inspections are carried out as required at all times. Locate the components that have experienced significant wear and replace them as soon as possible. This will prevent the wear from spreading to other areas and causing additional issues.

Your actions will show that you are responsible for the conditions under which employees are expected to work. The machinery will experience faster wear and tear as a result of poor working conditions; therefore, it is important to take the appropriate steps to reduce the impact that these conditions have on the machinery. Poor working conditions will hasten the wear and tear that the machinery experiences. The substandard working conditions will directly lead to an acceleration in the rate of wear and tear experienced by the machinery. When constructing a machine, it is absolutely necessary to make use of components that are not only of a high quality but have also been subjected to a rigorous testing process. When constructing a machine, it is critical to make use of components that have undergone rigorous testing prior to their incorporation.

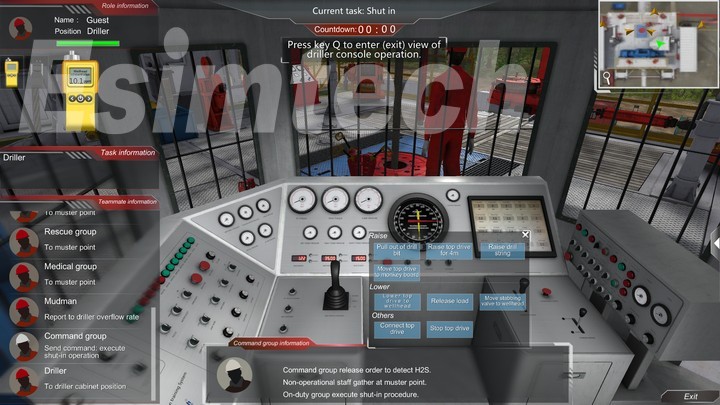

Give careful consideration to the processes of assembly and alignment: In order to guarantee that the mechanical parts are balanced and coordinated, you will need to correctly assemble and align those parts. 5. Give careful consideration to the processes of assembly and alignment. Assembly and alignment are both processes that require careful consideration on your part. Incorrect assembly and alignment can be the cause of abnormal friction and wear that can occur between mechanical parts. This can occur when there is contact between the parts. This might happen if the two parts come into contact with one another. Increase the coating protection by applying a specific coating treatment to the surface of the mechanical parts, such as a hard coating, a lubricating coating, or something else entirely. This can be done in a number of different ways. This can be accomplished in a variety of different ways depending on the situation. Depending on the circumstances, this can be accomplished in a number of different ways that are available. Install a system that will provide an early warning signal and monitor the wear that is occurring on mechanical components. Establish a monitoring and early warning system for mechanical wear, determine the wear situation in advance, and take corresponding maintenance measures by monitoring key parameters and real-time data.

This will help reduce the amount of downtime caused by mechanical wear. Because of this, you will be able to cut down on the amount of downtime brought on by mechanical wear. Because of this, you will be able to reduce the amount of downtime that is caused by the wear and tear of the mechanical components.7. Make preventative maintenance a regular part of your schedule by establishing a routine. Create an all-encompassing plan for maintenance that takes into account the product's expected service life, the conditions under which it will be used, and the recommendations of the manufacturer.

2. Conceive of a method for the documentation of the facility's maintenance and put it into practiceEstablish a dependable method for recording maintenance, and make it a point to document every aspect of the process, including the nature of each maintenance job, the amount of time it took, the person who performed it, and the components that were replaced. In addition, make sure that you have a reliable method for recording maintenance. In addition, you should make sure that the method you select for recording maintenance is auditable before moving forward. With the help of these records, which also serve as a reference for the reader, esimtech.com is possible to keep track of the device's maintenance history as well as its current status. This is something that is possible to do due to the fact that the records can also be used as a reference.

3. Providing the personnel who are responsible for maintenance with the appropriate training as well as opportunities to improve their skills in order to ensure that they have the appropriate knowledge regarding the technology and operations involved in maintenance. Make sure that the maintenance schedule is followed to the letter in every aspect. You ought to devise a method for ensuring that the maintenance plan is followed in its entirety in order to ensure that it is followed in its entirety. This can be done by ensuring that the plan is adhered to in its entirety. In addition to that, the plan needs to be carried out in a manner that is completely accurate.

5. Investigations and analyses of the current state of affairs that are still ongoing after performing routine checks and inspections on the machinery, determine whether or not the necessary maintenance has been carried out, and then carry out any necessary repairs as soon as possible after determining whether or not the maintenance has been carried out. Not only should the inspection cover the current state of the piece of equipment, but it should also cover its maintenance records and the legitimacy of any parts that have been repaired in the past. This is because the inspection should cover all three aspects. Check to see if the company you choose as your service provider can be relied upon.