Expanded Metal Mesh is a versatile and durable material that is widely used across various industries. Manufactured through a process of cutting and stretching a metal sheet, it forms a mesh with diamond-shaped openings, offering excellent strength-to-weight ratios and aesthetic appeal. This article delves into the features, applications, materials, and benefits of Expanded Metal Mesh, including variations like expanded aluminum, expanded steel mesh, expanded metal mesh stainless steel, and expanded wire mesh.

What is Expanded Metal Mesh?

Expanded Metal Mesh is created by simultaneously slitting and stretching a sheet of metal, forming a continuous mesh without welding or additional processing. The result is a strong, lightweight material that is both functional and decorative.

Common Variants:

• Expanded Metal: General-purpose mesh used in industrial and decorative applications.

• Expanded Mesh: Features standard and decorative patterns for diverse applications.

• Expanded Aluminum: Lightweight and corrosion-resistant, suitable for architectural and marine uses.

• Expanded Steel Mesh: Offers strength and durability, ideal for heavy-duty applications.

• Expanded Metal Mesh Stainless Steel: Resistant to rust and high temperatures, perfect for harsh environments.

• Expanded Wire Mesh: Includes finer openings, often used for filtration and screening.

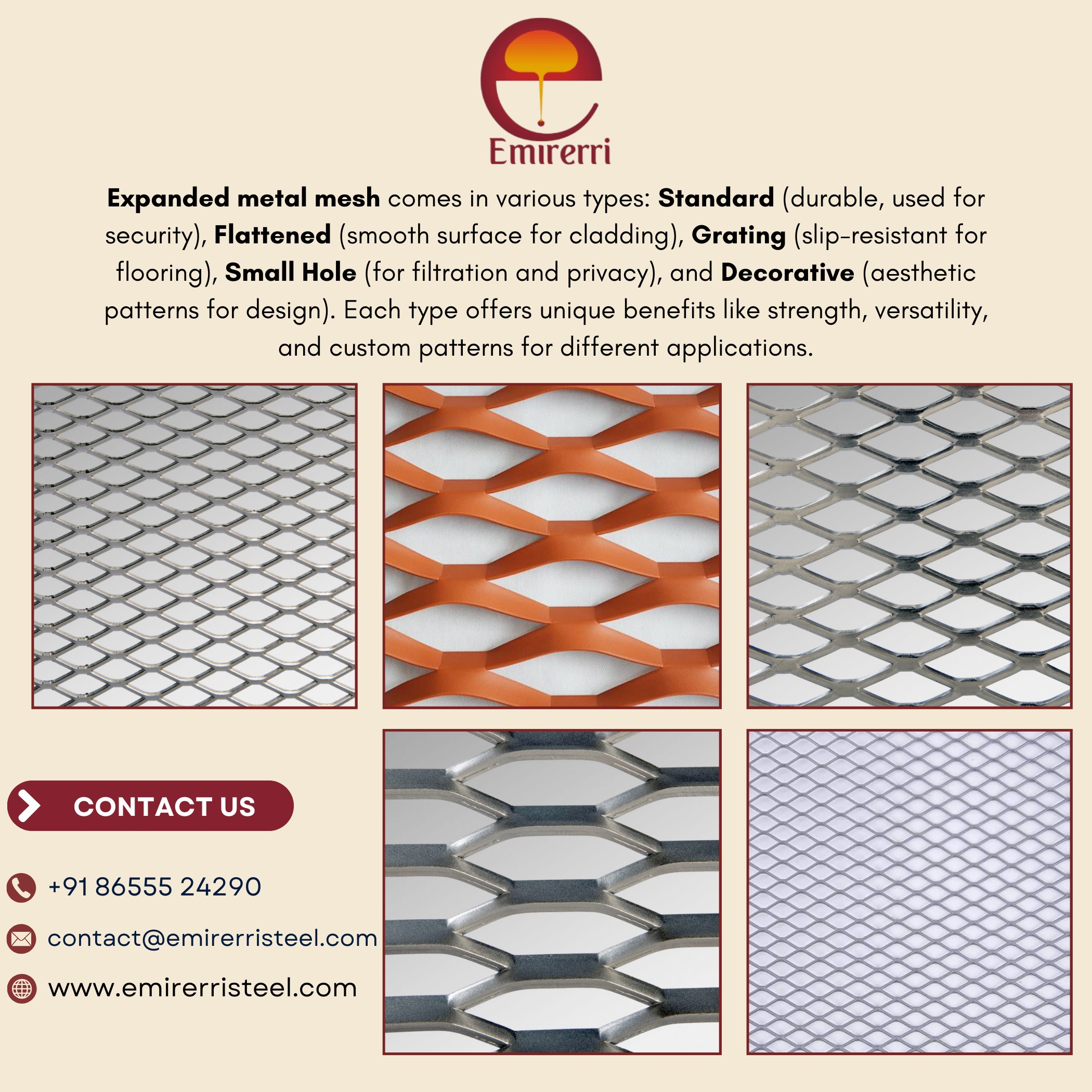

Types of Expanded Metal Mesh

1. Standard Expanded Metal

o Features raised strands and openings.

o Provides strength, rigidity, and slip resistance.

o Commonly used for walkways, ramps, and security applications.

2. Flattened Expanded Metal

o Made by pressing standard expanded metal to create a smooth, flat surface.

o Ideal for applications requiring a sleek aesthetic finish.

o Often used in architectural and decorative projects.

3. Expanded Metal Grating

o A heavy-duty mesh designed for high load-bearing applications.

o Suitable for industrial flooring, catwalks, and stair treads.

4. Small Hole Expanded Metal

o Characterized by smaller openings for fine filtration or precise screening.

o Frequently used in sieves, filters, and delicate enclosures.

5. Decorative Expanded Metal

o Comes in intricate patterns for aesthetic purposes.

o Used in facades, interior design, and decorative partitions.

Features of Expanded Metal Mesh

1. Strength and Durability: Maintains structural integrity while being lightweight.

2. Ventilation and Transparency: Allows air, light, and sound to pass through.

3. Anti-Slip Properties: Ideal for walkways and industrial flooring.

4. Customizable Designs: Available in a variety of patterns, sizes, and materials.

5. Eco-Friendly Production: Minimizes material waste compared to perforated sheets.

Applications of Expanded Metal Mesh:

1. Construction and Architecture

o Facades and cladding for buildings.

o Decorative elements like ceilings, partitions, and fencing.

o Safety screens and enclosures.

2. Industrial Use

o Walkways, stair treads, and platforms with anti-slip surfaces.

o Machinery guards and protective enclosures.

o Filters and ventilation grilles for industrial equipment.

3. Automotive and Transportation

o Grilles, reinforcement panels, and protective screens.

o Cargo barriers and storage compartments.

4. Agriculture and Fencing

o Animal enclosures and garden fencing.

o Trellises for plants and crops.

5. Decorative Applications

o Interior design features such as wall panels and screens.

o Custom artwork and modern architectural projects.

Materials Used in Expanded Metal Mesh:

• Carbon Steel: Affordable and strong, often used in heavy-duty environments.

• Stainless Steel: Corrosion-resistant and durable, ideal for harsh or marine environments.

• Aluminum: Lightweight and corrosion-resistant, commonly used in architectural projects.

• Copper and Brass: Offers unique aesthetic appeal for decorative applications.

• Nickel Alloys and Titanium: Specialized materials for high-performance industrial uses.

Benefits of Expanded Metal Mesh

1. Cost-Effective: Maximizes material usage, minimizing waste during production.

2. Durability: Strong and long-lasting, even in demanding environments.

3. Versatility: Suitable for functional, decorative, and safety applications.

4. Lightweight: Easier to handle and install compared to solid sheets.

5. Aesthetic Value: Offers a modern and stylish appearance for architectural designs.

Expanded Metal Mesh Sheets Expanded Metal Mesh Sheets are pre-cut sheets ready for immediate use. These sheets are available in standard sizes and patterns, making them convenient for various applications, including DIY projects, fencing, and industrial installations.

Expanded Wire Mesh Expanded Wire Mesh features finer openings compared to standard mesh. This type is widely used for filtration systems, sieves, and protective screens, where precision and smaller apertures are required.

Conclusion

Expanded Metal Mesh is a versatile material offering strength, durability, and aesthetic appeal across industries. Whether you need a lightweight option like expanded aluminum or a robust solution like expanded metal mesh stainless steel, the range of materials and applications ensures that there is a suitable mesh for every requirement. Its cost-effectiveness and eco-friendly production make it a preferred choice in modern construction, industrial, and decorative projects.